As gas moves through a pipeline its pressure and temperature change due to the frictional loss, elevation change, acceleration, Joule-Thompson effect, and heat transfer from the surroundings. Due to pressure and temperature change, liquid and solid (hydrate) may also form in the line which in turn affects the pressure profile. Modeling and simulation of multiphase system, even under steady-state condition, is complex. There are a few tools designed specifically for modeling and analysis of complex multiphase systems such as PipePhase, PipeSim, OLGA, etc [1]. This Tip of the Month illustrates how general-purpose process simulation programs can be used to simulate wet pipelines.

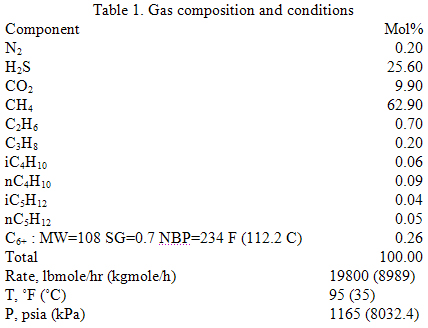

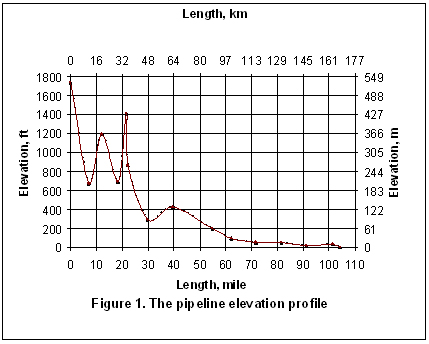

In order to perform computer simulation, let’s consider the gas shown in Table 1. The gas enters a pipeline with an inside diameter of 18.81 inches (47.8 cm) at rate of 180 MMSCFD equivalent to 19800 lbmole/hr (8989 kgmole/h). The pipeline length and elevation profile are shown in Figure 1. The ambient temperature is assumed to be 60 °F (15.6 °C). The gas enters the line at 1165 psia (8032 kPa) and 95 °F (35 °C). The pipeline is buried under ground; with an approximate overall heat transfer coefficient of 1 Btu/hr-ft2-°F (5.68 W/m2-°C) was assumed. Due to the high content of H2S and CO2 (25.6 and 9.9 mole %, respectively) and to prevent corrosion and hydrate formation, the gas has been dehydrated before entering the pipeline.

The calculation algorithms for computer simulation are discussed in the Gas Conditioning & Processing, Vol 3, Computer Applications for Production/Processing Facilities [2]. The pipeline was divided into 14 segments according to the number of up-hills and down-hills in the line. In addition, each segment was divided into 10 equal increments to achieve higher calculation accuracy. The pipeline was simulated by HYSYS [3], ProMax [4] and EzThermo [5] programs. For pressure drop calculation, the Beggs and Brill method with the original liquid hold up correlation was chosen in all three programs. The SRK equation of state (EOS) was chosen in the ProMax and EzThermo but PR EOS was chosen for HYSYS.

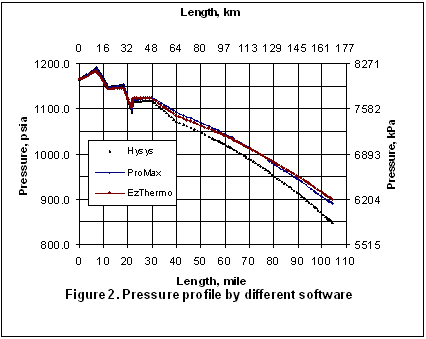

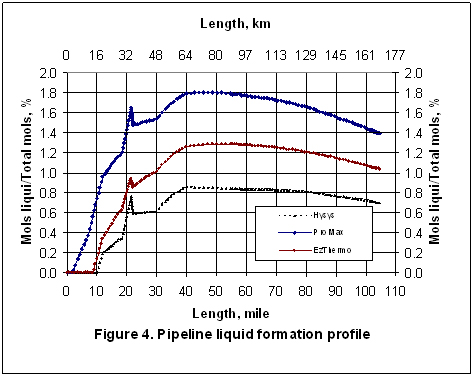

Figures 2 through 4 present the pressure, temperature, and liquid formation profiles along the pipeline. Figure 2 indicates that the pressure profiles predicted by the three programs follow the same pattern and ProMax and EzThermo results are very close to each other. The main difference in the calculated outlet pressure is due to the different amount of liquid formation predicted from phase behavior.

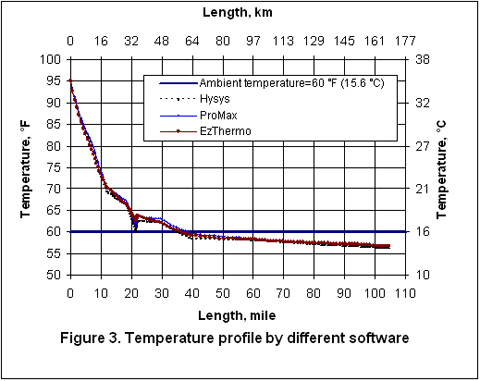

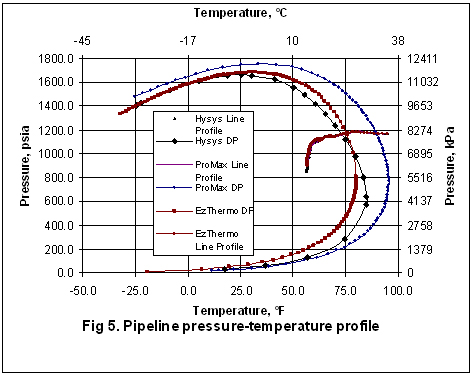

Figure 3 indicates that the temperature profiles predicted by the three programs fall on top of each other. It seems that the small amount of liquid condensation in the line has a smaller effect on the temperature profile than on the pressure profile. The liquid formation profiles predicted by the three programs are shown in Figure 4. As shown in this figure, the amount of liquid formation in the line predicted by ProMax is relatively higher than the other 2 programs. This can be explained by viewing the dew point curves predicted by these programs on Figure 5. Note that the cricondentherm predicted by ProMax is higher than the other two. As we have shown in an earlier tip of the month and publication [6], the characterization of heavy ends has a strong effect on the dew point curve and consequently on the liquid condensation in transmission lines [7]. In this study, the same normal boiling point, relative density, and molecular weight for C6+, as shown in Table 1, are used in all three programs. However, the critical properties predicted by these programs were not quite the same. In addition, the binary interaction parameters between different components and C6+ are not the same. Pipe surface roughness also play an important role for friction pressure drop in gas pipeline. It is interesting to see that the line pressure-temperature profiles by the three programs are practically the same despite the differences in the phase envelope.

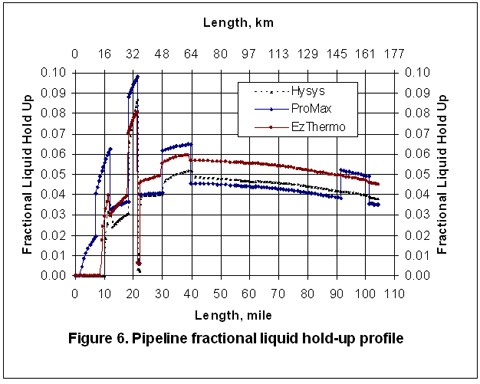

The fractional hold-up along the pipeline calculated by the three programs are shown in Figure 6. Even though all three programs demonstrate the same trends, those predicted by HYSYS and EzThermo follow each other more closely.

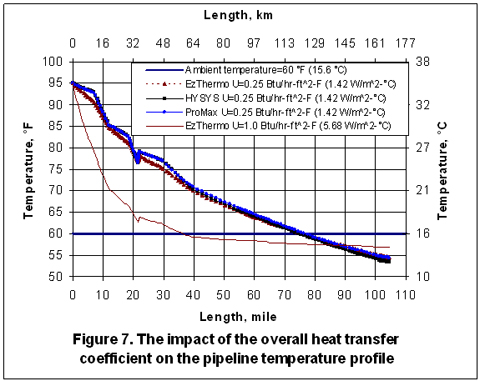

In line with our earlier tip of the month and in order to see the impact of the overall heat transfer coefficient on the pipeline behavior, the overall heat transfer coefficient of 1 Btu/hr-ft2-°F (5.68 W/m2-°C) was changed to 0.25 Btu/hr-ft2-°F (1.42 W/m2-°C). The simulation results indicate that the overall heat transfer coefficient can affect the line behavior considerably. The effect of the overall heat transfer coefficient on the temperature profile predicted by the three programs is presented in Figure 7.

The work reported here clearly shows the importance of simulation tools and how general-purpose process simulation programs can be used to model and analyze the behavior of a gas transmission pipeline. However, care must be taken to utilize these programs properly. Improper use of the overall heat transfer coefficient or heavy end characterization can lead to completely erroneous conclusions about the presence or absence of liquid, even to indicate as far as a pipeline will be handling dry gas when in reality the line will be in two phase gas – liquid flow.

Note: The Liquid-Gas ratio at the pipeline outlet in bbl/MMSCF [m3/106 std m3] are: 3.676 [20.95], 5.479 [31.23], and 7.352 [41.92] for HYSYS, EzThermo, and ProMax, respectively.

Proper use of the simulation programs combined with correct input of design parameters will lead to more accurate and reliable forecasts of gas pipeline behavior. The overall heat transfer between the line and its surroundings has an impact on liquid formation in the line and, consequently, on the line pressure profile.

Similar cases of fluid flow are discussed in our Fundamentals of Onshore and Offshore Pipeline Systems – PL-4, Onshore Pipeline Facilities – Design, Construction and Operations – PL-42, Flow Assurance for Pipeline Systems – PL-61, courses.

By: Dr. Mahmood Moshfeghian

References:

- Ellul, I. R., Saether, G. and Shippen, M. E., “The Modeling of Multiphase Systems under Steady-State and Transient Conditions – A Tutorial,” The Proceeding of Pipeline Simulation Interest Group, Paper PSIG 0403, Palm Spring, California, 2004.

- Maddox, R. N. and L. L. Lilly, Gas Conditioning and Processing, Vol. 3 (2nd Edition), Campbell Petroleum Series, Norman, Oklahoma, 1990.

- Aspen HYSYS, Version 2006, Engineering Suit, Aspen Technology, Inc., Cambridge, Massachusetts, 2006.

- ProMax Version 2.0, Process Simulation Software by Bryan Research & Engineering, Inc., Bryan, Texas, 2008.

- EzThermo, Moshfeghian, M. and Maddox, R. N., 2008.

- Moshfeghian, M., Lilly, L., Maddox, R. N. and Nasrifar, Kh., “Study Compares C6+ Characterization Methods for Natural Gas Phase Envelopes,” Oil & Gas Journal, 60-64, November 21, 2005.

- Dustman, T, Drenker, J., Bergman, D. F.; Bullin, J. A., “An Analysis and Prediction of Hydrocarbon Dew Points and Liquids in Gas Transmission Lines,” Proceeding of the 85th Gas processors Association, San Antonio, Texas, 2006