Does it annoy you that in spite of regularly performing Preventive Maintenance (PM) on your equipment it continues to breakdown? Some may call this insanity – Continuing to do the same thing over and over, expecting a different result.

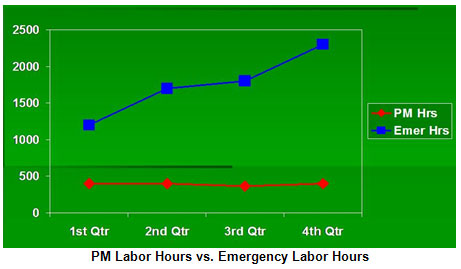

If you sat down and graphed out your companies’ PM labor hours versus emergency labor hours what would you find? In the chart below we find PM labor hours flat however emergency labor hours rising which indicates the PM program is not effective.

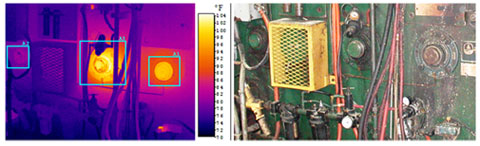

Have you ever heard of “Killer PMs”? These are PMs which are intrusive and are known to quite commonly cause premature failure of an asset. One such example might be taking a pump out of service to inspect coupling shaft alignment. Consider carefully that this inspection could be easily performed using Infrared Thermography or vibration analysis without shutting down the pump. Have you ever seen someone lubricate an electric motor with sealed bearings? These PMs sound unnecessary don’t they? But they happen every day.

Is this happening to you?

PMs can also absorb resources which could be used for work that would actually improve your reliability. Remember the challenge of reliability is the detection of a defect early enough that a part or equipment change out or repair can be planned and scheduled in a proactive state.

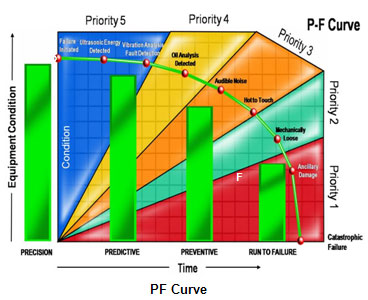

The example below displays the P-F Curve where the “P” is the point where a defect can first be detected maintenance strategy.

In the graphic above, it is important to notice that Predictive Maintenance allows one to detect a defect closer to “P” than Preventive Maintenance.

“It Isn’t What You Know That Will Kill You,

It Is What You Don’t Know That Will”

Did you realize that most Preventive Maintenance programs have not been engineered, they just evolved? With every regulation or component failure, both the number of PM tasks and the frequency of the tasks being executed increases, until it consumes 30-50% of your workforce and you are lulled into a false sense of security that you have evolved into a Best Practice or World Class organization.” Let’s be clear, it is impossible to evolve into Best Practice, it must be carefully engineered.

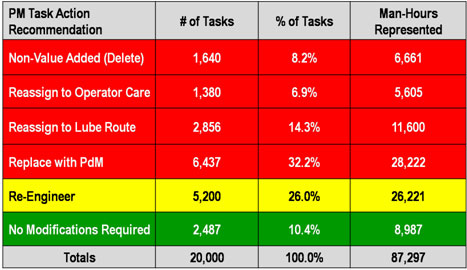

In fact, after numerous benchmarking studies, data states factually that most maintenance organizations are doing almost exactly the same type of maintenance they’ve always done. Now here’s the scary part. A closer look at all Preventive Maintenance (PM) tasks reveals that on average:

- 30% don’t add value and should be eliminated

- 30% should be replaced with Predictive Maintenance (PdM) tasks

- 30% could add value if re-engineered

What that means to you is, less than 10% of your PMs are truly adding value as written. Or, in other words, potentially, 90% of your PM tasks should be eliminated or changed. What’s worse, when you conduct unnecessary, invasive maintenance, you actually introduce variability and potential defects into your asset and process reliability. That’s right! You are actually causing some failures and you don’t even know it!

What to do about the problem?

Striking the right balance of Preventive and Predictive Maintenance is absolutely necessary and it offers a rare opportunity to save millions of dollars through:

- Lower maintenance costs

- Lower spare parts inventories

- Lower energy consumption

- Better safety performance

- Increased throughput capacity

Achieving these results is not easy. For starters, you need to have a common vision, a basic implementation strategy and a clear understanding of what’s required for success. Let’s look at the 6 most important steps you can take to begin achieving your reliability goals.

- Receive training in PM/PdM Best Practices.

- Update your functional hierarchy so that you have a clear understanding of the machines in your facility and their component configuration.

- Conduct a Criticality Assessment on your assets. You know, the assessment you used to help determine maintenance strategy, prioritize work orders and make better overall risk management decisions.

- Develop a complete understanding of the failure modes that are present or may be present in your components. These failure modes come from 2 places: 1) the inherent design of the machine and 2) the operating context in which they are used on a daily basis.

- Perform a Preventive Maintenance Evaluation (PME) where you identify each PM Task and any connection it may have to a failure mode you are experiencing. Are the PMs causing the failure or addressing it? If they aren’t addressing and reducing failures, then they add no value.

- Then believe in the outcome of your PME. If it says a PM adds value, do it! If it shows it doesn’t, then re-write/re-engineer it so it does, re-assign it to the appropriate PdM Technologies or get rid of it! See the chart below.

PetroSkills and JM Campbell offers workshops this year on this specific subject, “Introduction to Condition Monitoring” in Orlando, FL and Fort McMurray, Alberta, Canada (go to www.petroskills.com) or if you are interested in attending a one hour webinar on this subject contact Ricky Smith at smithr@alliedreliability.com. The webinar is scheduled for July 25, 2008 by JM Campbell and PetroSkills.

By Ricky Smith CMRP, PetroSkills Reliability Discipline Leader