There are different process configurations for adsorption dehydration systems. The most common arrangements are two-tower and three-tower configurations. One can find the details of the adsorption dehydration process and the descriptions of equipment in Chapter 18 of John M. Campbell textbook [1]. Figures 1 and 2 present a simplified process flow diagram for two-tower and a three-tower configurations, respectively. These units can reduce the water content of a gas stream to less than 0.1 ppmv. The gas industry normally uses adsorption dehydration units upstream of a liquefied natural gas (LNG) plant or a deep natural gas liquid (NGL) extraction plant where the gas temperature reduces to less than -160 °C (-256 °F) and -100 °C (-148 °F), respectively. Removal of water content to this very low level is essential to prevent freezing.

![Figure 1. A simplified process flow diagram for a two-tower adsorption dehydration system [1].](http://www.jmcampbell.com/tip-of-the-month/wp-content/uploads/2015/10/fig1.png)

Figure 1. A simplified process flow diagram for a two-tower adsorption dehydration system [1].

In the three-tower configuration, at any time two towers (e.g. A and B) in staggered parallel adsorption while the third tower (e.g. C) is regenerating. In this configuration, half of the feed gas flow rate is going through tower A and the other half passes through tower B as shown in the cycle chart embedded in Figure 2.

![Figure 2. A simplified process flow diagram for a three-tower adsorption dehydration system [1].](http://www.jmcampbell.com/tip-of-the-month/wp-content/uploads/2015/10/fig2.png)

Figure 2. A simplified process flow diagram for a three-tower adsorption dehydration system [1].

This month’s TOTM compares the required size of major equipment for the two-tower system with the three-tower system. The comparison considers the following parameters.

- Mass of Desiccant

- Bed Diameter

- Bed Height

- Regeneration Gas Rate

- Regeneration Heating Load

- Regeneration Cooling Load

- Regeneration Gas Heater Load

- Tower wall thickness and mass

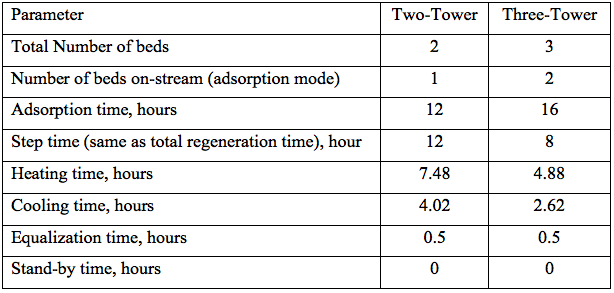

Table 1 presents descriptions of the two configurations.

Table 1. Tower configurations

This discussion assumes a gas volume rate of 2.83×106 Sm3/d (100 MMSCFD) with externally insulated towers. It examines two feed conditions of:

a. 30°C (86°F) and 6.207 MPaa (900 psia)

- Estimated water content = 699 kg/106 Sm3 (43.7 lbm/MMSCF)

- 2-Tower water load per tower per hour = 4 kg/h (182 lbm/hr)

- Water load per tower per cycle = 989 kg (2185 lbm)

- 3-Tower water load per tower per hour = 2 kg/h (91 lbm/hr)

- Water load per tower per cycle = 662 kg (1456 lbm)

- 2-Tower water load per tower per hour = 4 kg/h (182 lbm/hr)

b. 40°C (104°F) and 8.0 MPaa (1160 psia)

- Estimated water content = 974 kg/106 Sm3 (61 lbm/MMSCF)

- 2-Tower water load per tower per hour = 115 kg/h (254 lbm/hr)

- Water load per tower per cycle = 1378 kg (3050 lbm)

- 3-Tower water load per tower per hour = 5 kg/h (127 lbm/hr)

- Water load per tower per cycle = 920 kg (2033 lbm)

- 2-Tower water load per tower per hour = 115 kg/h (254 lbm/hr)

The other specified parameters are:

- Desiccant = Molecular Sieve Type 4A, 3.2 mm (1/8 in) diameter

- Desiccant loading capacity, ΔXnew = 19 wt% (mass of water/100 mass of desiccant)

- Desiccant life factor FL = 0.6 (Based on 3 years and average performance)

- Desiccant density = 705 kg/m3 (44 lbm/ft3)

- Desiccant heat capacity = 1.0 kJ/kg-°C (0.24 Btu/lbm-°F)

- Steel heat capacity = 0.5 kJ/kg-°C (0.12 Btu/lbm-°F)

- Feed gas relative density = 0.7

- Regeneration dry lean gas relative density = 0.59

- Regeneration gas pressure = 2.07 MPa (300 psia)

- Regeneration gas temperature to the heater = Feed gas temperature

- Regeneration gas temperature from heater = 288 °C (550 °F)

- Final bed regeneration temperature prior to cooling = 260 °C (500 °F).

Calculation Results

Based on the procedure and steps of Chapter 18 [1], this TOTM utilized a revised version of PetroSkills/Campbell GCAP software [4] to perform all of the calculations.

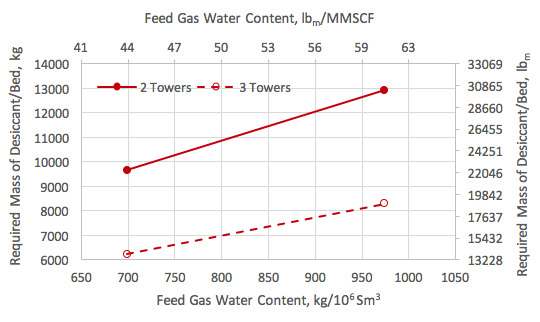

Figure 3A shows variation of the required mass of desiccant per tower with the feed gas water content for two and three-tower systems. As the feed water load increases, the required mass of desiccant increases for the specified and constant adsorption time. Note that the feed water load increases with increase in temperature and decrease in pressure. The water load per tower is a function of the feed water content, adsorption time and gas flow rate through the tower.

Figure 3A. Mass of desiccant per tower vs the feed gas water content and number of towers

The adsorption cycle times chosen for the two-tower and three-tower systems (12 hours and 16 hours, respectively) result in essentially the same total mass of water being adsorbed by both configurations. The total required mass of desiccant for the two-tower and three-tower systems are different because the length of mass transfer zone for the 3-tower system is lower than for the 2-tower system. Since desiccants are sold in 300 lbm (136.1 kg) increment, the mass of desiccant in each tower was rounded up to the next 300 lbm (136.1 kg).

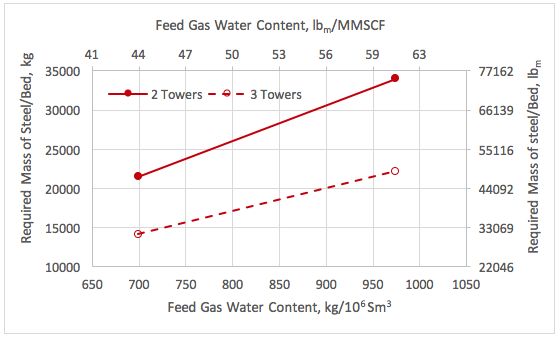

The calculated total mass of desiccants for the two-tower system are 19323 and 25855 kg (42600 and 57000 lbm) for the feed with the lower and higher water content, respectively. The corresponding desiccant masses for the three-tower system are 18779 and 25719 kg (41400 and 56700 lbm). Similarly, Figure 3B presents the required mass of steel per tower as a function of feed gas water content and number of towers.

Figure 3B. Mass of steel per tower vs the feed gas water content and number of towers

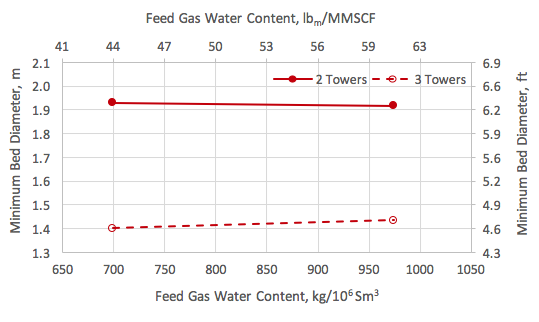

The mass of the desiccant in the tower and pressure drop criteria establish the tower diameter and height of desiccant. This is a trial and error calculation. Figure 4 shows variation of the minimum required bed diameter with the feed gas water content and number of towers. Since the gas flow rate per tower of the two-tower system is two times higher than the gas flow rate per tower in the three-tower system, the diameter of each tower in the two-tower system must be larger to meet pressure drop criteria of less than 41 kPa (6 psi). Figure 4 indicates that the limiting factor is the pressure drop and the feed gas water content has small effect on the bed diameter. The calculated superficial gas velocity for all cases ranged from 0.10 to 0.15 m/s (20 to 30 ft/min).

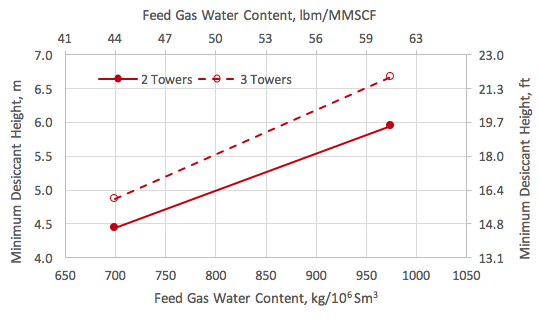

After determining the bed diameter, one can calculate the desiccant height from the mass of desiccant, bed diameter, and the desiccant density. Figure 5 shows the variation of the minimum desiccant height with the feed gas water content and number of towers. This figure indicates that feed with higher water content requires a taller bed and feed with lower water load requires shorter bed height. Since the diameter in two tower system was larger its height is shorter.

Figure 4. Bed diameter vs the feed gas water content and number of towers

Figure 5. Desiccant height vs the feed gas content and number of towers

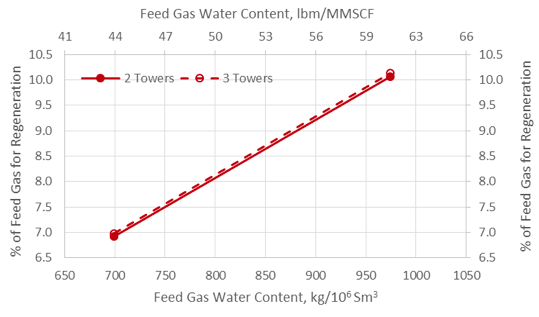

Figure 6 shows the variation of the regeneration gas requirement with the feed gas water content while maintaining constant heating and cooling times. This figure indicates that higher feed gas water content require more regeneration gas. However, the required regeneration gas rate is practically the same for the two-tower and three-tower systems under evaluation.

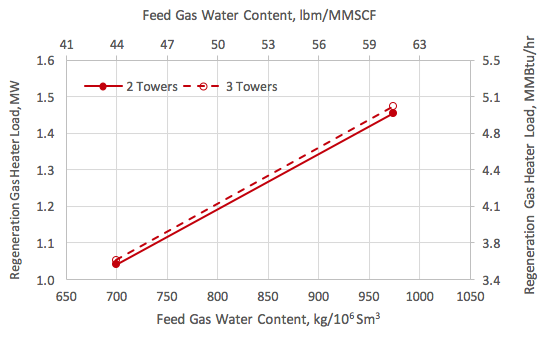

Figure 6. Percent of % feed gas for regeneration vs the feed gas water content and number of towers

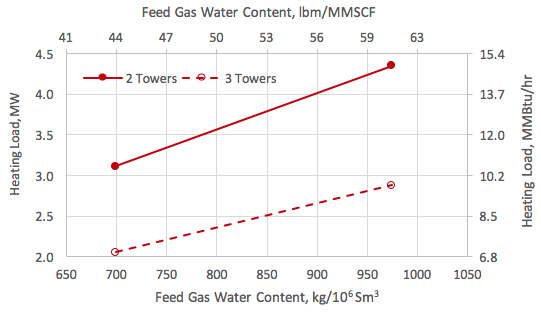

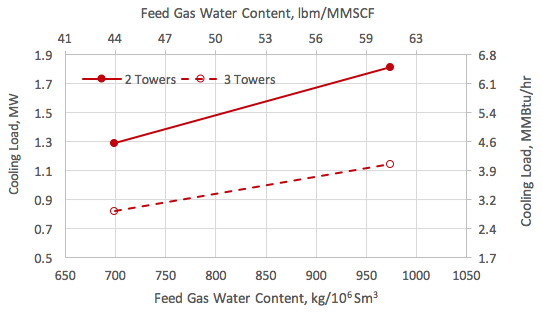

Similarly, Figures 7, 8, and 9 show the variation of the required heating load, cooling load, and regeneration gas heater load, with the feed gas water content and number of towers. Since the towers in the two-tower system are larger than the towers in the three-tower system, the heating and cooling loads are larger for the towers in the two-tower systems (figures 7 and 8). However, Figure 9 indicates that the required regeneration heater loads are almost the same for the two-tower and three-tower systems.

Figure 7. Heating load vs the feed gas water content and number of towers

Figure 8. Cooling load vs the feed gas water content and number of towers

Figure 9. Regeneration gas heater load vs the feed gas water content and number of towers

Summary:

Water content of the feed gas affected by temperature, pressure and flow rate is the key factor in sizing and operation of adsorption dehydration system. Higher water load requires a larger size bed, higher heating and cooling loads and higher rate of regeneration gas.

In the cases evaluated in this Tip of the Month, the tower diameters in the two-tower systems are larger but their heights are shorter. The mass of desiccants and mass of steel per tower in the two-tower system are larger than in the three-tower system. Therefore the heating and cooling loads are larger for the towers in the two-tower system. The regeneration gas heater loads are almost the same for two and three-tower system.

To learn more about similar cases and how to minimize operational problems, we suggest attending our PF49 (Troubleshooting Oil and Gas Facilities), PF42 (Separation Equipment Selection and Sizing), G4 (Gas Conditioning and Processing), G5 (Gas Conditioning and Processing – Special), and PF4 (Oil Production and Processing Facilities), courses.

PetroSkills offers consulting expertise on this subject and many others. For more information about these services, visit our website at http://petroskills.com/consulting, or email us at consulting@PetroSkills.com.

Dr. Mahmood Moshfeghian

References:

- Campbell, J.M., Gas Conditioning and Processing, Volume 2: The Equipment Modules, 9th Edition, 2nd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum Series, Norman, Oklahoma, 2014.

- Malino, H. M., http://www.jmcampbell.com/tip-of-the-month/2015/05/benefits-of-standby-time-in-adsorption-dehydration-process/

- Moshfeghian, M., http://www.jmcampbell.com/tip-of-the-month/2015/10/what-is-the-impact-of-feed-gas-conditions-on-the-adsorption-dehydration-system/

- GCAP Version 9.1.1, Gas Conditioning and Processing Software, Editor Moshfeghian, M., PetroSkills/Campbell, Norman, Oklahoma, 2015.

Wonderful I was wondering about how to modify the equations in the book for LPG dryers e.g. coolingvthe bed with dry LPG