This tip is the follow up of January 2017 tip of the month (TOTM) [1] which investigated a non-refluxed condensate stabilizer column having a split design where a portion of the feed is pre-heated by heat exchange with the bottoms product (see also page 352 of Reference [2]). The remainder of the feed is fed to the top tray, similar to a standard “cold feed” stabilizer. That tip simulated the performance of a split-feed and non-refluxed condensate stabilizer column equipped with a stripping sweet gas stream to reduce the H2S content of a sour condensate. It reported that decreasing the top feed-split from 100% to 80 %, decreases the required reboiler duty and the bottom product temperature, but increases the stabilized condensate TVP (True Vapor Pressure) and H2S content.

This tip will perform computer simulation to study the effect of pressure on the performance of a non-refluxed stabilizer column with the same split-feed design. This tip will consider stabilizing a sour condensate for RVP (Reid Vapor Pressure) specification of 7 psi (48 kPa). The tip will report the impact of the column operating pressure on the reboiler duty, top and bottom temperatures, stabilized condensate rate, H2S content, and TVP. The tip will present a summary of the computer simulation results and the key diagrams for the same plant.

Case Study

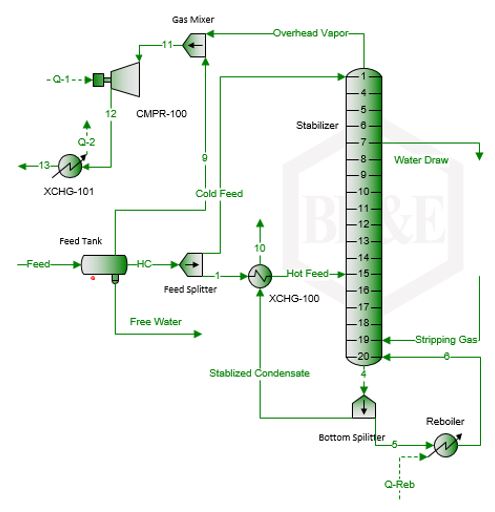

Figure 1 presents a simplified process flow diagram equipped with the preheater, stripping gas and water-draw tray for stabilization and sweetening of raw sour condensates.

Figure 1. A non-refluxed stabilizer column with feed-split, side water-draw and stripping gas

The 3-phase separator upstream of the preheater removes essentially all excess/free water. The tip utilizes a feed splitter to heat up a portion of feed in the preheater by the hot stabilized condensate. The stripping sweet gas stream lowers the H2S content of the stabilized condensate and achieves the desired condensate vapor pressure at the specified reboiler temperature. Three cases of column pressures were considered. For the comparison purposes and regardless of the specified 3-phase separator and column pressure, the separated gases from the 3-phase separator and the stabilizer column are compressed and cooled to specified pressure of 255 psia and temperature of 90 °F (1758 kPaa and 32 °C) in the compressor and cooler shown in the top-left side of this figure.

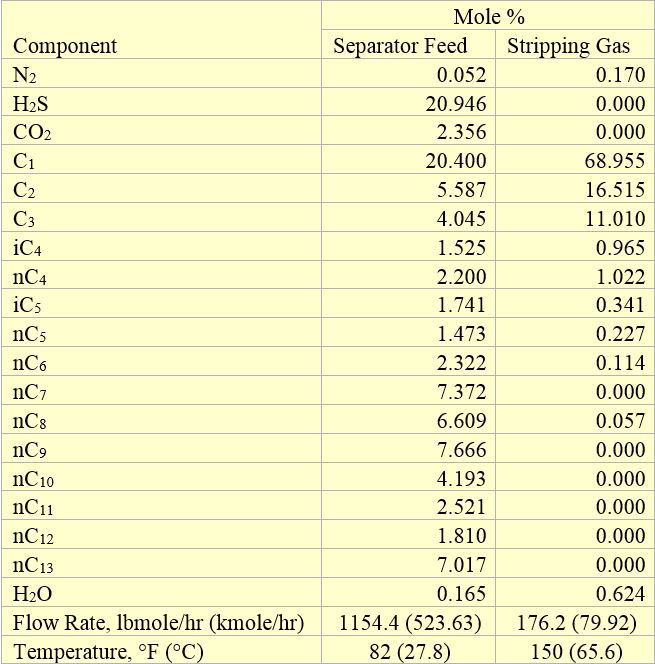

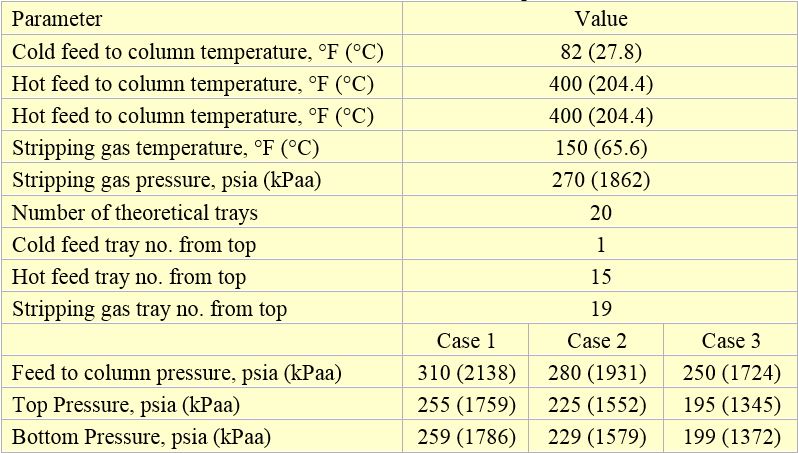

Table 1 presents the raw condensate, containing about 21 mole % H2S, and stripping gas compositions, rates and conditions. Table 2 presents the specified column variables. The condensate stabilizer column specifications for the three cases studied are shown in Table 2. For all three cases, the 3-phase separator pressure was 5 psi (35 kPa) higher than the column feed pressure.

Table 1. Feed and stripping gas compositions, rates and conditions

Table 2. Condensate stabilizer column specifications

Simulation Results

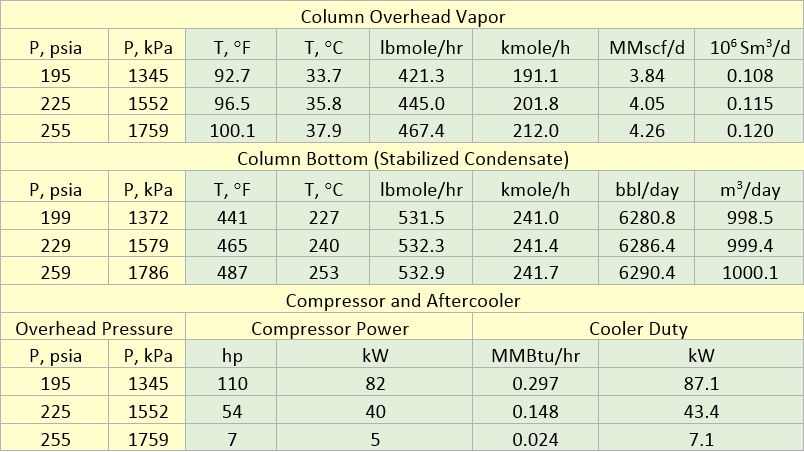

Based on the data in Tables 1 and 2, and the process flow diagram of Figure 1, the tip performed simulation using the Soave-Redlich-Kwong (SRK) equation of state [3] in ProMax [4] software. Similar to the previous tip the bottom-splitter ratio was adjusted to meet the specified RVP of the stabilized condensate. Table 3 presents the summary of results for the three specified cases. This table indicates that decreasing the specified 3-phase separator and column pressure decreases the bottom and overhead rates, bottom and overhead temperatures, but increases the compressor power and cooler duty. At lower pressures, more gases are separated in the 3-phase separator and feed rate to the column is reduced. Therefore, the bottom product (stabilized condensate) and overhead product rates decrease. In addition, decreasing column pressure increases the relative volatility (the K-value ratio of the key components) making separation of components easier and hence the required reboiler duty decreases.

The results presented in Table 3 are practically independent of the top-feed split which varied from 80 to 100 % with an increment of 2%. The values presented in Table 3 are the calculated arithmetic averages for the top-feed split range of 80 to 100%. The simulation results for those variables which were dependent on the top-feed split are shown graphically in the following figures.

Table 3. Summary of simulation results for three specified column pressures

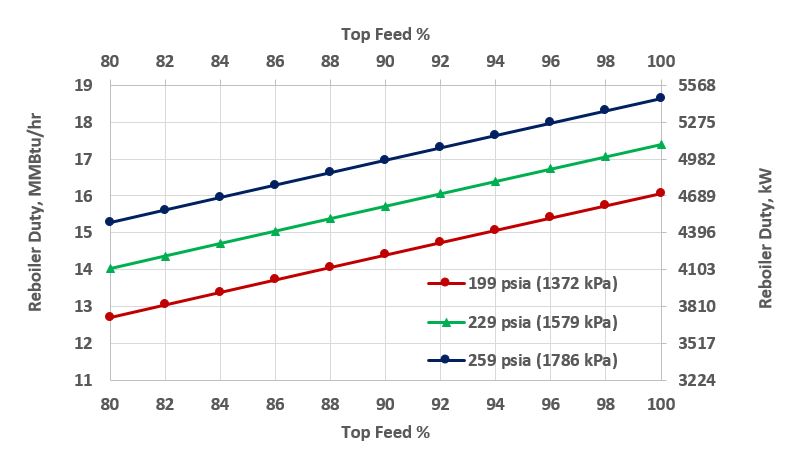

Figure 2 presents the required reboiler duty as a function of the top feed-split and the specified column bottom pressure. This figure indicates that decreasing column bottom pressure decreases reboiler duty and the reboiler duty increases linearly with the top feed-split %. At a specified column pressure, increasing top-feed spilt decreases the hot-feed rate to column and hence increases the reboiler duty. However, the installation of the preheater reduced the required reboiler duty by about 19% for the case of top feed-split of 80% due to the heat recovery from the hot bottom product (stabilized condensate).

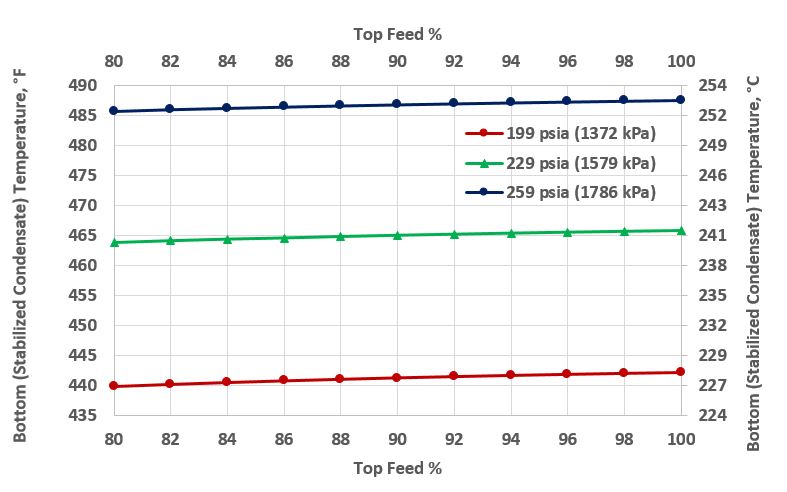

Figure 3 presents the variation of stabilized condensate temperature as a function of the top feed-split. Decreasing the top feed-split from 100 to 80%, decreases the bottom product temperature by about 2 °F (1.1 °C) for the three specified bottom pressures. Decreasing the specified column pressure, decreases the bottom temperature because component vapor pressure and temperature are directly related.

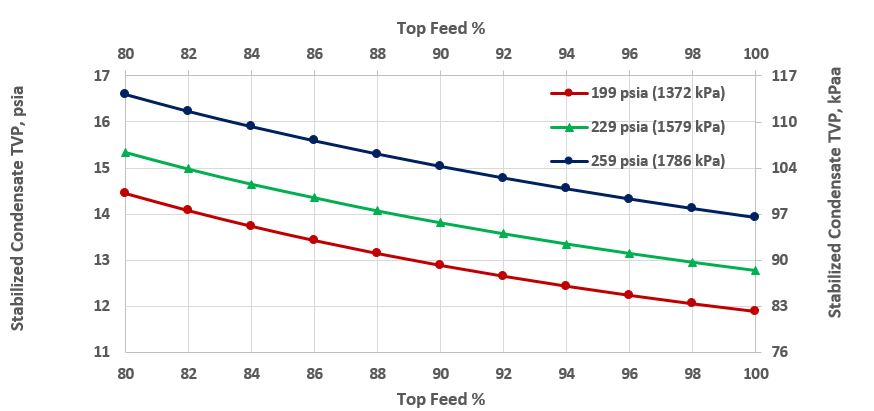

Figure 4 presents the variation of stabilized condensate TVP as a function of the top feed-split and column bottom pressure. Decreasing the top feed-split, increases the stabilized condensate TVP by about 2.6 psi (18 kPa) for the three specified bottom pressures.

Figure 2. Effect of top feed-split on reboiler duty for three column bottom pressures

Figure 3. Effect of top feed-split on bottom temperature for three column bottom pressures

Figure 4. Effect of top feed-split on stabilized condensate TVP for three column bottom pressures

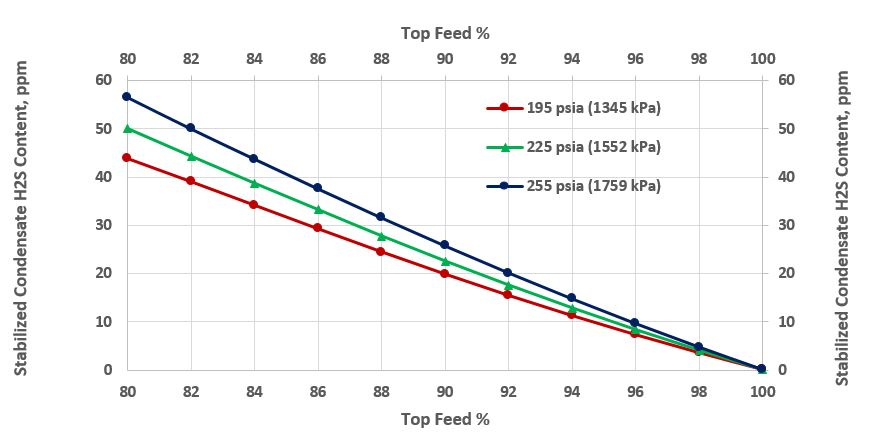

Figure 5 presents the variation of H2S content of the stabilized condensate as a function of top feed-split and column overhead pressure. This figure indicates that decreasing the top feed-split from 100 to 80%, the stabilized condensate H2S content increases by about 44, 50, and 56 ppm for bottom pressure of 195, 225, and 255 psia (1345, 1552, and 1759 kPaa), respectively. This figure also indicates that for all three cases:

- the H2S content is below the limit of 60 ppm,

- the higher the top-feed %, the better the H2S stripping,

- H2S stripping is better and easier at lower pressure.

It should be noted that since the raw feed condensate leaves the feed tank (three phase separator) saturated with water but with no free water, simulation resuts showed no liquid water being trapped in the column. Therefore, no water was removed by the water-draw tray in all cases studied in this tip. Still it is advised to keep the water draw-off capabilities on the top trays.

Figure 5. Effect of top feed-split on stabilized condensate H2S content for three column overhead pressures

Conclusions

This tip investigated the impact of column and 3-phase separator pressures on the performance of a split-feed and non-refluxed stabilization column by varying the top feed-split from 80 to 100% by an increment of 2 % for three pressure specifications. Based on the simulation results, this tip presents the following observations.

Decreasing the 3-phase separator and column pressures,

- decreases the required reboiler duty (Figure 2)

- decreases the bottom product temperature (Figure 3)

- decreases the stabilized condensate TVP (Figure 4)

- decreases the stabilized condensate H2S content (Figure 5)

- increases the required compressor power and cooler duty (Table 3)

- decreases the stabilized condensate rate (Table 3)

To learn more about similar cases and how to minimize operational problems, we suggest attending our G4 (Gas Conditioning and Processing), G5 (Practical Computer Simulation Applications in Gas Processing), and PF4 (Oil Production and Processing Facilities), courses.

PetroSkills offers consulting expertise on this subject and many others. For more information about these services, visit our website at http://petroskills.com/consulting, or email us at consulting@PetroSkills.com.

By: Dr. Mahmood Moshfeghian

Reference:

- Moshfeghian, M., January 2017 TOTM, PetroSkills | John M. Campbell, 2017.

- Campbell, J.M., Gas Conditioning and Processing, Volume 2: The Equipment Modules, 9th Edition, 2nd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum Series, Norman, Oklahoma, 2014.

- Soave, G., Chem. Eng. Sci. 27, 1197-1203, 1972.

- ProMax 4.0, Bryan Research and Engineering, Inc., Bryan, Texas, 2016.

I read this post completely about the resemblance of latest and preceding technologies, it’s

awesome article.