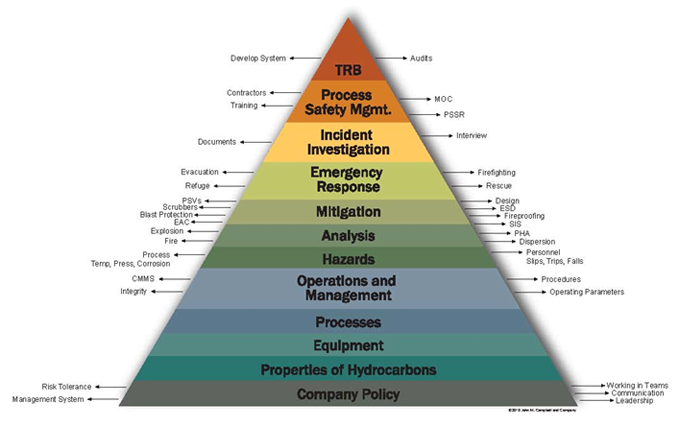

In the April, 2011, Tip of the Month (TOTM), we looked at a simple, graphical representation of process safety competency. This TOTM will follow up on that by asking a simple question:

“When examining catastrophic incidents, what are the typical mistakes that engineers make?”

This question was asked of me at a lunch and learn session I conducted for a client where I had described the competency pyramid introduced in the April TOTM. At the time, I thought, what a good question. I replied, I have to think about that. After reflecting for a bit, I went to the pyramid.

Looking at the pyramid, it seems to me that a lot of an engineer’s duties revolve around the “Equipment” and “Mitigation” levels. It is here that separators are sized; pumps are chosen; inherently safer design is incorporated into a process; safety instrumented systems (SIS) are designed; pressure safety valve (PSV) sizing is calculated. Refer to the April TOTM again. “To become a well rounded professional in the oil and gas industry, no matter what specialty position a person works in, requires varying degrees of competency in many different areas of expertise. Obtaining higher level competencies is a continuous process of training and performing tasks, sometimes under the direction of a mentor or coach.”

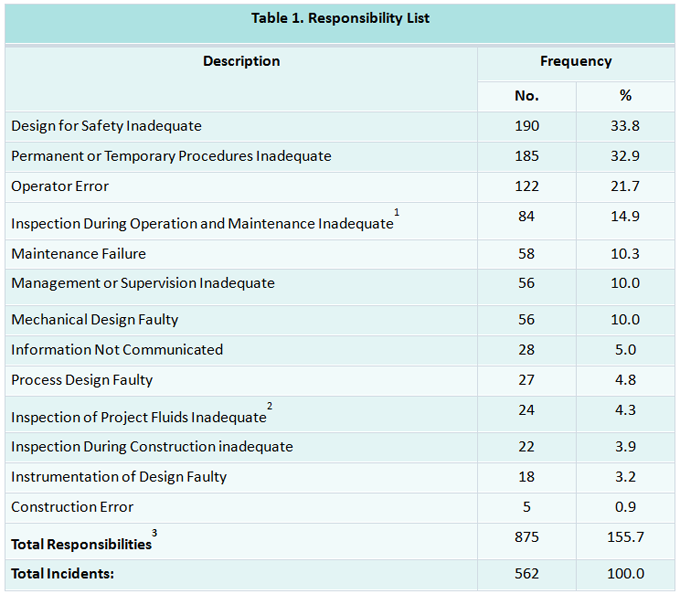

It could be that the typical mistakes made by engineers are a result of competency with equipment and mitigation measures. Consider some information from JMC’s Process Safety Engineering course, PS 4. This table lists the area of responsibility for incidents [1].

Notes:

- The item “inspection during operation” includes some items that are not always the responsibility of the inspection department:

- Vibration monitoring for rotating equipment.

- Corrosion probes

- The item “inspection of process fluids” includes:

- Flammable-gas detection in shutdown, and in tanks during operation

- Inspection of purchased and process fluids to determine whether they are the ones specified.

- The average incident has 1.56 responsibilities

How many of the items on the list are engineering functions and which of them could be related to competency? I suppose it could be argued that almost all are related to engineering functions if it is accepted that engineers provide the design, recommend inspections and maintenance tasks, provide significant information needed for development of operating procedures and have historically been assigned management responsibilities in the oil and gas industry. Which are related to competency? That is much more difficult to answer and could only be answered by individual organizations based on performance reviews and competency mapping.

The April, 2010, TOTM discussed the need to perform a good job task analysis to identify personal and process safety hazards. While the checklist presented there can be modified to allow engineering personnel to analyze engineering tasks, there is a simpler way to insure that engineers reduce the likelihood of mistakes in their work. Ask the following six questions about any project or job that is being done. If each question is answered fully, the job should be performed mistake free.

- What are we doing? — A very simple description of what is required to perform the task.

- What is the most dangerous part? — To find the most dangerous part, all hazards will have to be identified.

- What will we do to protect ourselves? — Plan for the worst.

- How will we know that we are changing what we are doing?—Insures that scope creep doesn’t happen.

- What will we do about it? — Contingency planning prior to problems being encountered.

- How will we know we are done? — Should be able to identify everything that needs to be in place when finished.

It is difficult to determine the typical mistakes, related to technical competency, made by engineers that cause or could reasonably cause a catastrophic incident. Root cause analysis can usually discover breakdowns in an organization’s process safety management system. Using the six questions to analyze work prior to starting and periodically throughout the life of a project may help to keep personnel focused on the consequences of failure and reduce the likelihood of failure. Thus, reducing risk.

Several JMC courses develop competencies associated with the equipment and mitigation levels of the competency pyramid. To learn more about process safety for engineers, consider attending a session of our PS 4, Process Safety Engineering course.

John M. Campbell Consulting (JMCC) offers consulting expertise on this subject and many others. For more information about the services JMCC provides, visit our website at www.jmcampbellconsulting.

By: Clyde Young

Reference:

- Ian Duguid, “Take This Safety Database to Heart”, Chemical Engineering Magazine, July 2001.

I would be very interested to hear what you think are typical mistakes that engineers make associated with process incidents. I’m especially curious about technical mistakes, if they exist.

Try the questions and see if they help focus your efforts.

Clyde

not investigating for root cause/ quick to blame: In one incident the hot oil piping was shaking violently. The process engineer puts the blame on low quality hot oil and asked for a free replacement. I looked at the equipment drawing, did some calculations and found that the real culprit is a defective design where the heating coils was installed in parallel and the oil velocity was below the recommended minimum. Had the oil be replaced it would have degraded (after a certain time) as before.

І’m new to building sites and I was wondering if having your website title relevant to your content really that important? I see your title, “Campbell Tip of the Month | ” does seem to be spot on with what your blog is about however, I prefer to keep my title less content descriptive and based more around site branding. Would you think this is a good idea or bad idea? Any kind of assistance would be greatly appreciated.