In the March 2011 tip of the month (TOTM) we studied a constant volume translation of liquid density method presented by Peneloux et al. [3] and demonstrated its application for pure components. Considerable improvements were obtained, specifically for the low temperature range (reduced temperature < 0.8), of saturated specific volume (or liquid density) predicted by Soave-Redlich-Kwong (SRK) [1] and Peng-Robinson (PR) [2], but, the constant volume shift fails near the critical temperature. In the July 2011 TOTM, we reviewed several temperature dependent volume correction methods [3-11]. They improved the accuracy of liquid density prediction considerably near the critical point region.

As the extension of the March and July 2011 Tips of the Month in this TOTM we will demonstrate application and accuracy of some of these methods to predict liquid density of light hydrocarbon mixtures encountered in gas processing. We will compare their accuracy against both experimental data and a few correlations.

Equations of state (EoS) are used in commercial simulation software for predicting phase behavior and thermodynamic properties. The cubic equations of state give relatively accurate results for predicting vapor-liquid equilibria, especially for non-polar or slightly polar systems. These equations can be used to accurately predict vapor densities, enthalpy and entropy. These advantages encourage the researchers to augment EoS ability more than before, especially liquid density, although their accuracy for liquid density prediction is generally poor. The popular EoSs such as SRK [1] and PR [2] predict liquid density with an average absolute error of about 8%, much higher than several good density correlations. This large magnitude of error is not acceptable by industry; therefore, they are not used for this purpose. In order to overcome this deficiency, volume translated methods have been developed.

The correlations and volume translated methods [3-11] used in this study are the same as those presented in the July 2011 TOTM. Only those methods, which gave the best results for the cases studied in this TOTM, are described briefly here. More details about these methods can be found in the corresponding references.

- Correlations

The following correlations were used in this study.- COSTALD, 1979: The COSTALD correlation by Hankinson and Thomson [12] requires two parameters: wSRK, the optimized value of the acentric factor based on the SRK equation of state (EoS) and; V*, the pure component characteristic volume.

- RSD, 1972: Spencer and Danner [13] improved the liquid density correlation of Rackett [14]. The improved correlation for saturated liquid density calculation requires only ZRA, the improved compressibility factor.

- NM, 1998: Nasrifar and Moshfeghian [15, 16] presented an equation and a set of mixing rules for predicting the liquid density of pure refrigerants and liquefied natural gas.

- Volume Translated EoS Methods

Equation 1 is the basic volume translated (shift) method proposed by Peneloux et al. [3] and used in this study. Equations 2 and 3 utilize the Kay’s rule to estimate mixture molecular weight (MW) and volume shift correction parameter (c).

In the above equations, is the corrected liquid specific volume, is the liquid specific volume calculated by the EoS, MW is the molecular weight, ρL is the liquid density, and the correction term or volume shift factor “c” is determined from experimentally measured liquid density. The volume shift factor is normally regressed against several experimental data points. The following methods were used to determine c for the mixtures.

- Temperature Independent, PRF, 1982: Peneloux et al. [3] proposed the following expression to estimate the constant temperature volume shift correction for each component “i” in the mixture. In the absence of experimentally regressed value, it can be estimated as follows:

where ZRA, is the Rackett [15] parameter, R is the gas constant, and TC and PC are the critical temperature and pressure, respectively.

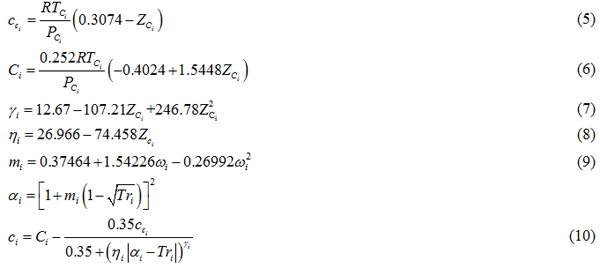

where ZRA, is the Rackett [15] parameter, R is the gas constant, and TC and PC are the critical temperature and pressure, respectively. - Temperature Dependent, AG, 2001: Ahlers and Gmehling [6] temperature dependent correction factor, c, is calculated as follows:(5)(6)

In the above equations, Tr is the reduced temperature, ω is acentric factor, TC, PC and ZC are component i critical temperature, pressure and compressibility factor, respectively. The correction term, c, from the above methods is substituted into equation 1 to calculate the corrected density.

Results and Discussion:

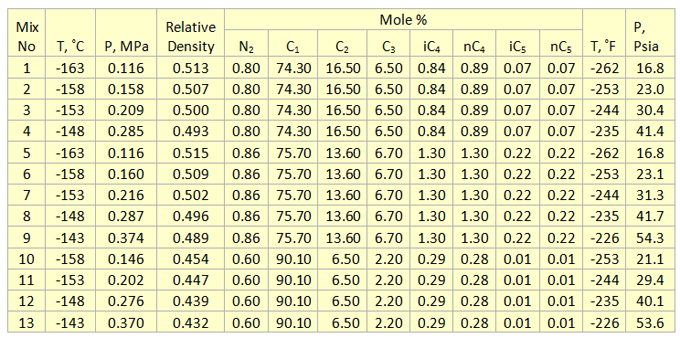

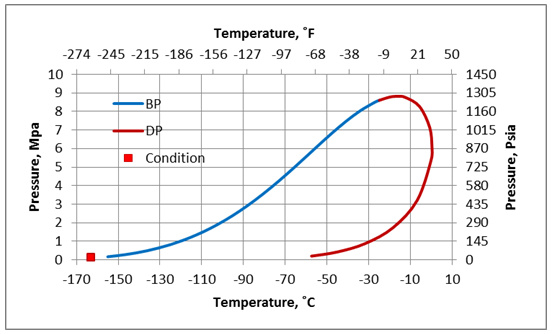

We applied the preceding methods to several natural gas mixtures shown in Table 1. The experimentally measured temperature, pressure, composition and relative liquid density for each mixture are shown in this table [17]. These mixtures and corresponding conditions represent those encountered in the cryogenic processes. As an example, the condition and phase envelope for mixture number 1 of Table 1 are presented in Figure 1.

Table 1. Experimentally measured composition, temperature, pressure and relative density for the mixtures studied [17]

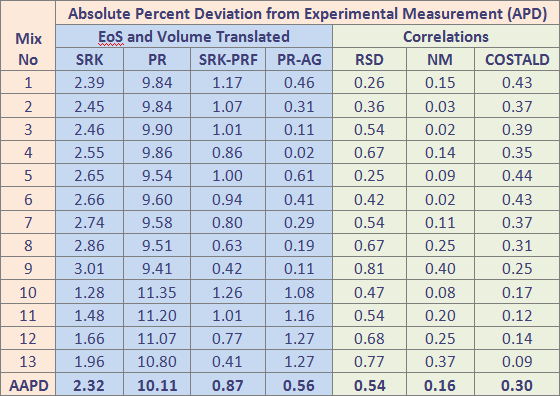

Table 2 presents the summary of the error analysis for the liquid density prediction by different methods for the natural gas mixtures shown in Table 1. As can be seen in Table 2, both SRK and PR EoSs give poor results; however, considerable improvements are observed by applying temperature-independent volume translated SRK (SRK-PRF) and temperature-dependent volume translated PR (PR-AG). The volume translated results for these mixtures are much closer to the results obtained by the three correlations of RSD, NM, and COSTALD.

To learn more about similar cases and how to minimize operational problems, we suggest attending the John M. Campbell courses; G4 (Gas Conditioning and Processing), and G5 (Gas Conditioning and Processing-Special).

John M. Campbell Consulting (JMCC) offers consulting expertise on this subject and many others. For more information about the services JMCC provides, visit our website at www.jmcampbellconsulting.

By Dr. Mahmood Moshfeghian

Figure 1. Phase envelope and liquid density condition for mixture 1

Table 2: Comparison of acuracy of EoS, volume translated EoS, and correlations for predicting liquid density of mixtures prsented in Table 1

Reference:

- Soave, G., Chem. Eng. Sci., Vol. 27, pp. 1197-1203, 1972.

- Peng, D. Y., and Robinson, D. B., Ind. Eng. Chem. Fundam., Vol. 15, p. 59, 1976.

- Peneloux, A. E., Rauzy, E., and Freze, R., Fluid Phase Equilib., Vol. 8, pp. 7-23, 1982.

- Tsai, J. and Y.P. Chen, J. of Fluid Phase Equilibria, Vol. 145, pp. 193-215, 1998.

- Ahlers, J. and J. Gmehling, J. of Fluid Phase Equilibria, Vol. 191, pp. 177-188, 2001.

- Lin, H. and Y.Y. Duan, J. of Fluid Phase Equilibria, Vol. 233, pp. 194-203, 2005.

- Ji, W.R. and D.A. Lempe, J. of Fluid Phase Equilibria, Vol. 130, pp. 49-63, 1997.

- Pfohl, O., J. of Fluid Phase Equilibria, Vol. 163, pp. 157-159, 1999.

- Magoulas, K. and D. Tassios, J. of Fluid Phase Equilibria, Vol. 56, pp. 119-140-445, 1990.

- Frey, F., Augustine, C., Ciccolini, R.P., Paap, S., Modell, M., and J. Tester, , J. of Fluid Phase Equilibria, Vol. 260, pp. 316-325, 2007.

- Frey, F., Modell, M., and J. Tester, J. of Fluid Phase Equilibria, Vol. 279, pp. 56-63, 2009.

- Hankinson, R. W., Thomson, G. H., AIChE J., Vol. 25, no. 4, pp. 653-663, 1979.

- Spancer, C. F., and Danner, R. P., J. Chem. Eng. Data, vol. 17, no. 2, pp. 236-241, 1972.

- Rackett, H. G., J. Chem. Eng. Data, vol. 15, No. 4, pp. 514-517, 1970.

- Nasrifar, Kh. and Moshfeghian, M., Fluid Phase equilibria Vol. 153, 231-242, 1998.

- Nasrifar, Kh. and M. Moshfeghian, J. of Fluid Phase Equilibria, Vol. 158-160, pp. 437-445, 1998.

- Haynes, W.M.J., J. Chem. Thermodyn., Vol 14, pp. 603–612, 1982.

would like to get monthly tip and any new technical update regarding HC measurement & forum.

I have found a software, Prode Properties which includes extended versions of Peng Robinson and Soave Redlich Kwong giving results much more accurate than Peneloux translation,

with water I am able to calculate liquid density from melting point up to 0.95 * critical with errors of about 2-3 % ,

in addition to these versions of Peng Robinson and Soave, Prode includes the Cubic Plus Association model which is even more accurate, water densities are predicted with errors less that 1-2%

A important thing when simulating a plant is that in addition to densities several other properties as latent heats, specific heats etc. must be predicted with good accuracy, differently you get wrong results…

With Prode (Peng Robinson) I get for latent heats of water and glycol (in a range of temperatures) errors less than 2-3% meaning that if I am going to size a heat exchanger I get reasonably accurate numbers.

the published data are very interesting and I thank you for the article,

I would suggest to mention in the list also the extended Peng Robinson and Soave Redlich Kwong included in Prode Properties, Prode has specific parameters calculated for best fitting of vapor pressure, liquid density and latent heat of many pure compounds including hydrocarbons and polar fluids as water, glycols etc. that means that you get an average error of less than 2% for water or glycol liquid density and latent heats.

That is an important factor when simulating a gas dehydration plant.

Also Prode includes CPA PR and SRK, these are very accurate with associating fluids as water and glycol, I have tested accuracy for calculated values of water liquid density, average errors are about 1% from melting point temperature up to 0.95 * critical point.

I think this information could interest many engineers.