In March 2013 (TOTM), we estimated capital costs (CAPEX) as a tool to compare then select the operating conditions and associated facilities for a long distance – high volume flow gas transmission pipeline located onshore.

In this month’s Tip of the Month (TOTM), we will consider the same cases discussed in the January 2013 (TOTM) and continue to explore alternatives specifically for offshore natural gas transportation. This month’s focus is on the estimation of capital costs as a tool to compare then select the operating pressures and associated facilities for a long distance, high volume flow gas transmission pipeline.

Case Study:

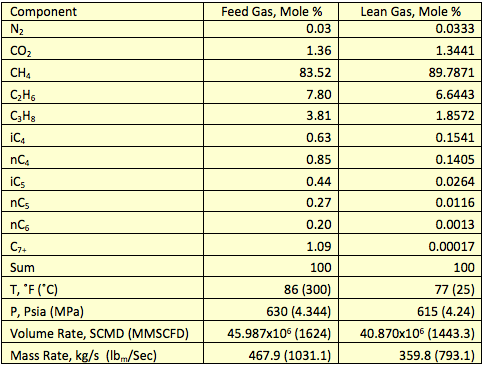

We will continue to use a similar case study basis as used in the March 2013 TOTM. The gas composition and conditions are presented in Table 1. For simplicity, the calculations and subsequent discussion will be done on the dry basis. The feed gas dew point was reduced to -40 ˚C (-40 ˚F) by passing it through a mechanical refrigeration dew point control plant. The resulting composition and conditions of the lean gas are also presented in Table 1. The lean gas has a Gross Heating Value of 40.33 MJ/Sm3 (1082 BTU/scf). The pipeline parameters are:

- Length is 1609 km (1000 miles) long

- Pipeline outside diameter is 1067 mm (42 inches) for cases A through C. Case D outside diameter is: 915 mm (36 in)

- Steady state conditions are assumed.

- Pressure at delivery point and suction at each intermediate compressor station is 7 MPa (1015 Psia)

- This is a horizontal pipeline with no elevation change.

- Overall Heat Transfer Coefficient: 5.678 W/m2-˚C (1.0 Btu/hr-ft2-˚F).

- Ambient temperature is 4.4˚C (40˚F).

- Pipeline inside surface roughness 46 microns (0.0018 inch)

- Density of carbon steel is 7850 kg/m3 (490 lbm/ft3)

- Compressor polytropic efficiency is 75%.

- Pressure drop in coolers 35 kPa (5 Psia)

- Simulation software: ProMax using Equation of State from Soave-Redlich-Kwong (SRK).

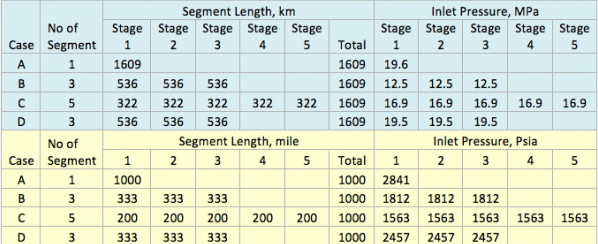

Four cases of offshore transportation of this natural gas are considered and each is explained briefly below. The number of pipeline segments, segment length, and inlet pressure of each segment for the four cases are presented in Table 2 in the SI (System International) and field or FPS (foot, pound and second) sets of units.

Table 1. Composition and conditions of the feed gas and lean gas

Table 2. Pipeline specifications for the four cases

Hydraulics Simulation Results and Discussions:

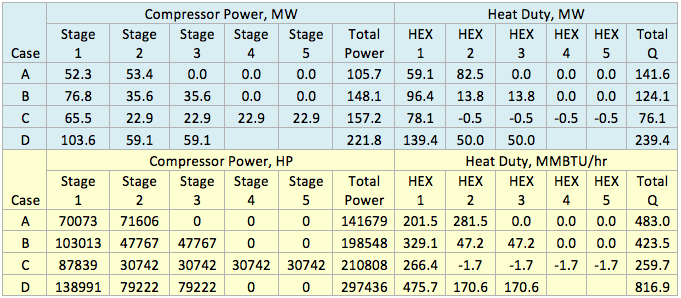

The four cases are simulated using ProMax [3] to determine the pressure and temperature profiles, the compression horsepower, and the after cooler duties. Table 3 presents a summary of simulation results for the three cases in FPS and SI systems of units. For Case A, Stage 1 and Stage 2 are located at the originating compressor station. For Cases B, C and D, Stage 1 (only) refers to the originating compressor station with Stages 2 and higher referring to intermediate booster compressor station(s).

Table 3. Summary of computer simulation results for the four cases.

Case A: High Pressure (Dense Phase)

This 42 inch (1067 mm) OD pipeline is a single compressor station configuration. The pipeline inlet pressure is in the dense phase zone. After processing and passing through the first stage scrubber, the lean gas pressure is raised from 4.24 to 9.122 MPa (615 to 1323 Psia), then cooled to 37.8 ˚C (100 ˚F). The gas is compressed further in the second stage to 19.623 MPa (2846 Psia). The high pressure compressed gas is cooled back to 37.8 ˚C (100 ˚F) and then passed through a separator before entering the long pipeline.

Case B: Intermediate Pressure

This 42 inch (1067 mm) OD pipeline has three compressor stations each equally spaced at 536 km (333 miles). The pipeline inlet pressure is near the dense phase zone. In the first station, the pressure is raised from 4.24 to 12.528 MPa (615 to 1817 Psia) and in the subsequent two stations, the pressure is raised from 7 to 12.528 MPa (1015 to 1858 Psia) in one stage, then cooled to 37.8 ˚C (100 ˚F), and finally passed through a separator before entering each pipeline segment.

Case C: Low Pressure

This 42 inch (1067 mm) OD pipeline has five compressor stations equally spaced in 322 km (200-mile) segments. In the first station, the pressure is raised from 4.24 to 10.777 MPa (615 to 1563 Psia) and in the subsequent four stations, the pressure is raised from 7 to 10.777 MPa (1015 to 1563 Psia) in one stage, then cooled to 37.8 ˚C (100 ˚F), and finally passed through a separator before entering each pipeline segment. The pipeline inlet pressure is well below that for dense phase.

Case D: High Pressure

This case is similar to case B except it operates in the dense phase with a 36 inch (914 mm) OD pipelines . This pipeline has three compressor stations each equally spaced at 536 km (333 miles). The pipeline inlet pressure is in the dense phase zone. After processing and passing through the first stage scrubber, the lean gas pressure is raised from 4.24 to 8.484 MPa (615 to 1230 Psia), then cooled to 37.8 ˚C (100 ˚F). The gas is compressed further in the second stage 16.975 MPa (2462 Psia). The high pressure compressed gas is cooled back to 37.8 ˚C (100 ˚F) and then passed through a separator before entering the pipeline. In each subsequent station, the pressure is raised from 7 to 16.975 MPa (1015 to 2835 Psia) in one stage, then cooled to 37.8 ˚C (100 ˚F), and finally passed through a separator before entering each pipeline segment.

As can be seen in Table 3, Case A with a single compressor station requires the least total compression power; however, it does not have the lowest heat duty requirements. The power increase for Case B (with three compressor stations) is about 40% compared to Case A and 49% and 83% for Cases C (with 5 compressor stations) and D (with 3 compressor stations), respectively. These increases in power and heat duty requirements are significant. Similarly, the heat duty changes are about (-)12, (-)46, and (+)43% for case B through D compared to case A, respectively.

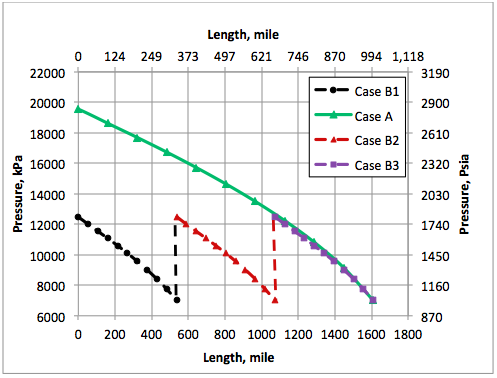

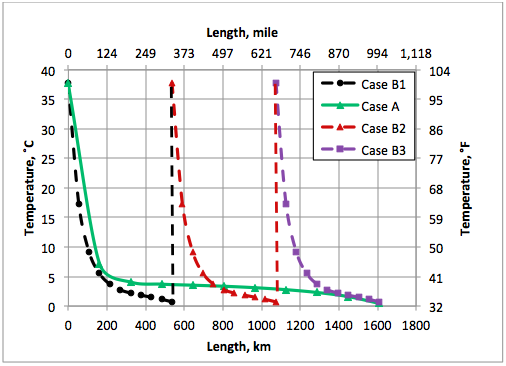

The gas pressure and temperature profiles are shown on Figures 1 and 2 for Cases A and B. As discussed in the previous TOTM, when the phase diagram and the pressure profiles are cross plotted using the pressure and temperature profiles the pipeline outlet condition remains to the right of the dew point curve and the gas stays as single phase.

Mechanical Design (Wall Thickness and Grade)

Pipeline wall thickness is an important economic factor. Pipeline materials have historically represented approximately 40% of the Capital Expense (CAPEX) of a pipeline. Construction has historically accounted for approximately 40% of the CAPEX as well. The estimation of the CAPEX is developed later in this TOTM. Once the wall thickness is determined, then the total weight (tonnage) of the pipeline can be calculated as well as the estimated costs for the pipeline steel.

Figure 1. Variation of pressure in the pipeline (Cases A and B)

Figure 2. Variation of temperature in the pipeline (Cases A and B)

The wall thickness, t, for the four cases is calculated from a variation of the Barlow Equation found in the ASME B31.8 Standard for Gas Transmission Pipelines:

![]()

Where,

- P is maximum allowable operating pressure, here set to 1.1 times the inlet pressure,

- OD is outside diameter,

- E is joint efficiency (assumed to be 1) since the pipeline will be joined with through thickness butt welds and 100% inspected,

- F is design factor,(ranges from 0.4 to 0.72) and here set to be 0.72 (for remote area),

- T is the temperature derating factor and is also 1.0 with the inlet temperatures no more than 37.8 ˚C (100 ˚F).

- σ is the pipe material yield stress (Grade X70 = 70,000 psi or 448.2 MPa), and

- CA is the corrosion allowance (assumed to be 0 in or 0 mm, for this dry gas).

- Onshore pipelines will have a maximum D/t of 42.

Using the calculated pipeline inlet pressures from the hydraulics as the starting point, the maximum allowable operating pressure (MAOP), and then the wall thickness can be calculated. The calculated wall thickness is then checked against the maximum D/t criteria. If the D/t calculated is too high, the wall thickness will be increased to yield the maximum allowed D/t.

The 10 % increase of the maximum calculated pipeline pressure to define the MAOP is conservative. Many operators use an increase of 3 to 7 % when defining the MAOP. There some operators that use the maximum calculate pipeline pressure in steady state flow as the MAOP.

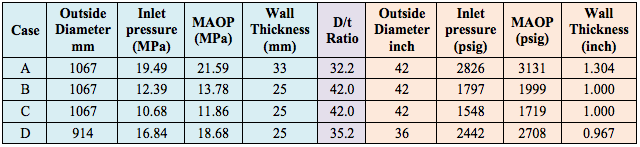

For Cases B and C the calculated wall thicknesses were 21 and 18 mm (0.820 and 0.701 inch) which resulted in D/t of 51 and 60, respectively. Therefore, the wall thickness was raised to 25.4 mm (1 inch) for both cases to meet the maximum value of 42. Finally, the hydraulic simulation was repeated for the adjusted wall thickness. Table 4 summarizes these calculations for the four cases of offshore locations.

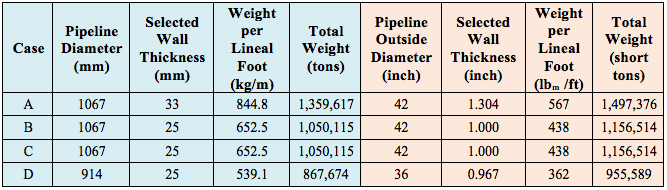

Knowing the wall thickness and diameter allows the weight per lineal length (foot or meter) to be calculated. The total weight of the steel for the 1609 km (1000 mile) long can be calculated as well. The unit weight is given in kg/m (lbm/ft) and the total weight is in metric tonnes (1000 kg) and short tons (2000 pounds). The results of these weight calculations are in Table 5.

Table 4: Pressures and Wall Thickness Selections

Table 5: Pipeline Wall Thickness Selections and Total Steel Weight

Some observations from these calculations are:

- Decreasing the pipeline diameter from 1067 to 914 mm (42 inch to 36 inch) reduces the total steel tonnage. This is due to the smaller diameter and, in Cases B and C , lower MAOPs decrease the wall thickness and resulting tonnages.

- Increasing the steel grade (SMYS – Specified Minimum Yield Stress) from X-70 to X-80 would decrease the steel tonnage approximately 14%. As the cost calculations will show, this reduction would lower the cost significantly.

- The steel grade (SMYS) for the pipe in Cases B and C could be reduced to X-60 with no change in the needed wall thickness. This might lead to a reduction in cost and may also improve some of the steel physical properties such as ductility.

- The volume of steel combined with the diameter and wall thicknesses will require a major portion of pipe manufacturing capacity. If this were a sanctioned project, pipe steel procurement would need to bid well in advance of the planned construction.

- Wall thicknesses are NOT raised to the next standard API thicknesses. The large quantity of steel needed allows the buyer to dictate a non-standard thickness. The pipe mills will usually be glad to accommodate such a requirement.

Estimated Capital Costs

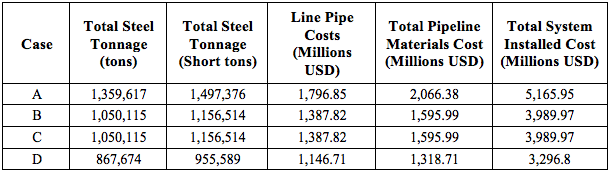

The capital costs (CAPEX) for these estimates are based on two key variables: pipeline wall thickness and the compression power required. Both are dependent on the pipeline pressure profile which is dictated by the number of compressor stations. The estimated cost will be calculated from the following assumptions:

- Line pipe is priced at US$ 1200 per short ton with a 15% adder for coatings.

- Pipeline total installed cost is 2.5 times the pipe steel plus coatings cost. This factor has been surprisingly consistent historically for both onshore and offshore long distance and larger diameter pipelines. Project specific factors such as weather limitations (weather “windows”) can impact this cost multiplier.

- No additional cost difference is taken into account for this estimate regarding many of the real conditions that are dealt with for the offshore design construction. In reality there is a difference that can be significant. These differences are largely dependent on the project location with factors that could include weather and seasonal challenges, available infrastructure (particularly ports) and its impact on logistics, and availability of construction equipment and labor.

- Compressors and associated equipment (drivers, coolers, and ancillaries) are priced at US$ 1500 per demand horsepower.

- Onshore compressor stations are priced at US$ 25 million each for site works, buildings and equipment not directly related to gas compression equipment.

- Offshore compressor stations are priced at US$250 million each for the fixed structure, topsides not directly related to gas compression equipment. This assumption is sensitive to project location, whether the structure is stand-alone or in a group of structures, water depth, level of manning, and met-ocean conditions.

- The offshore pipeline cases originate ONSHORE with the lead compressor station.

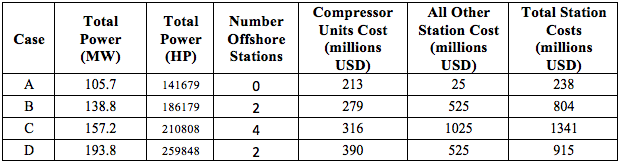

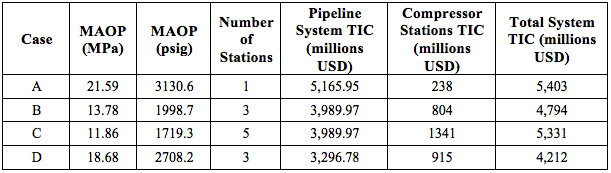

With these cost assumptions, an order of magnitude estimate (OME) for the total installed cost (TIC) is developed for the pipeline, then the compressor stations, and finally combined for the total OFFSHORE pipeline system in Table 6 – Pipeline Estimate, Table 7 – Compressor Station Estimate, and Table 8 – Total System OME.

Table 6: Pipeline Total Installed Cost – OFFSHORE SYSTEM

Table 7: Compressor Stations Total Installed Cost

Table 8: Total System OME

The results are indicative of finding sets of operating pressures, pipe diameter and number of compressor stations that show relatively little change with different combinations of the key parameters (Cases B and D). The selection of the “optimum” system configuration will involve more engineering definition, consideration of construction challenges, and evaluation of other parameters such as the operating costs (OPEX), environmental and permitting challenges, and more depth in evaluating the construction plan and costs.

For the smaller outside diameter – Case D, the total installed costs for this OFFSHORE system declines despite the increase in operating pressure (MAOP). The “optimum” configuration appears to favor smaller diameter pipelines with higher operating pressures and fewer compressor stations. The cost adjustments for project location on both CAPEX and OPEX can move to “optimum” configuration either way.

Often, with the operating costs included in the life-cycle costs, the “optimum” configuration favors higher operating pressures, smaller diameters, and fewer compressor stations. The cost adjustments for project location on both CAPEX and OPEX can move to “optimum” configuration either way.

Final Comments:

We have studied transportation of natural gas in the dense phase region (high pressure) and compared the results with the cases of transporting the same gas using intermediate pressures. Our study highlights the following features:

- There may be several system configurations (pipe diameter, operating pressures, and number of compressor stations) that show relatively small variation in TIC (Total Installed Cost).

- As the MAOP increases, the required power decreases and associated compression costs can significantly decrease.

- Decreased costs for compression are offset by increasing pipeline costs. The key is by how much.

- Project location can have significant impact on the costs, then on the key decisions of operating pressures, and the number and power levels at the compressor stations.

- With the power demands of large diameter – high capacity pipelines, the operating costs for fuel can be a key factor in the configuration selection. If the gas at the source is not at high enough pressure, considerable compression power and cooling duty may be required at the originating if the decision is to use the dense phase.

In future Tips of the Month, we will consider the effect of project location and operating costs on the life cycle costs and the configuration selection.

To learn more, we suggest attending our G40 (Process/Facility Fundamentals), G4 (Gas Conditioning and Processing), G5 (Gas Conditioning and Processing-Special), PF81 (CO2 Surface Facilities), PF4 (Oil Production and Processing Facilities), and PL4 (Fundamentals of Onshore and Offshore Pipeline Systems) courses.

John M. Campbell Consulting (JMCC) offers consulting expertise on this subject and many others. For more information about the services JMCC provides, visit our website at www.jmcampbellconsulting.com, or email us at consulting@jmcampbell.com.

By: Mahmood Moshfeghian and David Hairston

References:

- Beaubouef, B., “Nord stream completes the world’s longest subsea pipeline,” Offshore, P30, December 2011.

- http://www.jmcampbell.com/tip-of-the-month/

- ProMax 3.2, Bryan Research and Engineering, Inc., Bryan, Texas, 2012.

Hello, just wanted to tell you, I likeed this post. It

was inspiring. Keep on posting!

If for instance, the project is to take longer

than the expected, the homeowner should be given notice for the same.

Most locations also require inspections during certain phases of construction and a final

inspection when the work is complete. A Atlanta roofing contractor will be able

to properly install or repair roofing materials to ensure a quality finished product.

If yoou wish for to improve your familiarfity only keep visiting this web page and

be updated with the newest ijformation posted here.

Heree is myy site: top 10 vibration platform machines 2014 (Minerva)

The advanced flash apps are simply impressive and

there is no way that an enthusiastic gamer could control clear of these

types of games. Sitting down in a circle, each person says (holding the champagne cork) “this is

my pig, I love my pig, I kiss my pig on the ………,” each person says a

different body part and you kiss the cork before passing it on. If

your gaming console is not working, you will need to decide if you will buy a new one

or have it repaired.

Here is my homepage comment avoir une copine

Today, I went to the beach with my children. I

found a sea shell and gave it to my 4 year old

daughter and said “You can hear the ocean if you put this to your ear.” She put the shell

to her ear and screamed. There was a hermit crab inside and it pinched her ear.

She never wants to go back! LoL I know this is

completely off topic but I had to tell someone!

Here is my homepage; Fort Lauderdale Boat Show 2014 dates

A country is what the countrymen make it and countrymen of Bhutan are

the most peace loving beings one can ever come across thus making every tourist feel welcome in their land.

They also helped parents of a 13-month-old girl when they were laid off from

their jobs because of missing too much work to be with her.

The Phoenix area, in my opinion is the greatest winter golfing destination in the

US.

It’s very straightforward to find out any topic on web as compared to

books, as I found this post at this web page.

I every time spent my half an hour to read this webpage’s

articles or reviews daily along with a cup of coffee.

Wow, that’s what I was looking for, what a data!

present here at this website, thanks admin of this web site.

Feel free to surf to my site … ice cream maker reviews

Hi mates, how is everything, and what you would like to say about this post, in my view its truly awesome in support of me.

Hey there! Do you use Twitter? I’d like to follow you if that would be okay.

I’m undoubtedly enjoying your blog and look forward to new posts.

Hello to all, how is all, I think every one is getting more from this web site,

and your views are pleasant for new visitors.

I am regular reader, how are you everybody? This

paragraph posted at this site is in fact nice.

It’s very simple to find out any matter on net as

compared to books, as I found this article at this web site.

my weblog website; Kenton,

After I initially left a comment I appear to have

clicked on the -Notify me when new comments are added- checkbox and

from now on every time a comment is added I recieve 4 emails with the exact same comment.

Perhaps there is a means you are able to remove me from that service?

Thank you!

Excellent site you have here but I was wanting to

know if you knew of any forums that cover the same topics discussed here?

I’d really love to be a part of online community where I can get opinions from other knowledgeable individuals that share the same interest.

If you have any suggestions, please let me know.

Thanks a lot!

I reside within just southeast Missouri I grew up within Philadelphia ….. We contain no wawa my small children strategy I was ridiculous the moment I would say I need a wawa hoagie or say “WaWa” which includes the previous radio ads….. We have to have WaWa inside Missouri -D -D -D -D -D -D