Hydrogen sulfide and carbon dioxide are the principal objectionable acid gas constituents often present in natural gas, synthetic gas, and various refinery gas streams. These acid gas constituents must be removed for corrosion prevention in gas pipelines and process equipment and for health and safety reasons. Reference [1] provides current acceptable concentration levels for these acid gases in gas streams. Hydrogen sulfide removal is also often important for production of sulfur, which is used to create sulfuric acid and fertilizers. Carbon dioxide removal is also important for its capturing and sequestering, as well as for enhanced oil recovery.

In natural gas treating, there are several processes available for removing the acid gases. Aqueous solutions of alkanolamines are the most widely used [1]. The alkanolamines process is characterized as “mass transfer enhanced by chemical reactions” in which acid gases react directly or react through an acid-base buffer mechanism with an alkanolamines to form nonvolatile ionic species. For further detail of sour gas treating refer to references [1-4].

Several alkanolamines have been used for acid gas removal from natural gas streams. In this study only a primary monoethanolamine (MEA), a secondary diethanolamine (DEA) and a tertiary methydeithanolamine (MDEA) are considered. MEA has the highest reactivity and MDEA has the highest selectivity.

In this TOTM, we will study and compare the performance of these three amines by simulation of a simplified process flow diagram for removal of H2S and CO2 from a sour gas stream. The H2S and CO2 concentration in the sweet gas, amine solution circulation rate, reboiler duty, amine losses, pump power, and lean-rich heat exchanger (HEX) duty are calculated and plotted for a wide range of steam rates needed to regenerate the rich solution. In addition, the optimized steam rates and corresponding design variables are determined and reported.

Case Study:

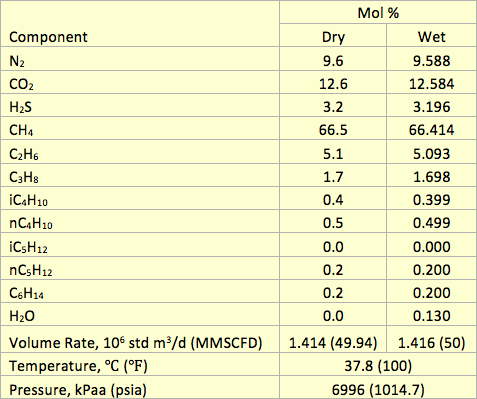

For the purpose of illustration, we considered sweetening of 1.416×106 std m3/d (50 MMSCFD) of a sour and wet natural gas with the composition, pressure, and temperature presented in Table 1. ProMax [5] simulation software with “Amine Sweetening – PR” property package was used to perform all of the calculations.

Table 1. Feed composition, volumetric flow rate and conditions

The following specifications/assumptions were made:

Contactor Column

- Feed sour gas is saturated with water

- Number of theoretical stages = 8

- Pressure drop = 35 kPa (5 psi)

- Lean amine solution temperature = Sour gas feed temperature + 5.5 (10)

Regenerator Column

- Number of theoretical stages = 11 (excluding condenser and reboiler)

- Rich solution feed temperature = 98.9 (210)

- Rich solution feed pressure = 245 kPa (35 psi)

- Condenser temperature = 48.9 (120)

- Pressure drop = 35 kPa (5 psi)

- Bottom pressure = 138 kPa (20 psig)

- Reboiler duty = Specified “Steam Ratio” times circulation rate (Refer to Table 2)

Heat Exchangers

- Lean amine cooler pressure drop = 21 kPa (3 psi)

- Rich side pressure = 41 kPa (6 psi)

- Lean side pressure = 35 kPa (5 psi)

Pump

- Discharge Pressure = Sour gas feed pressure + 35 kPa (5 psi)

- Efficiency = 65 %

Lean Amine Circulation Rate and Concentration

- Varied to meet the target acid gas loading in the rich solution shown in Table 2

Rich Solution Expansion Valve

- Pressure drop in first expansion valve (vlve 100) = 6310 kPa (915 psi)

- Pressure drop in the second expansion valve (vlve 101) = 303 kPa (44 psi)

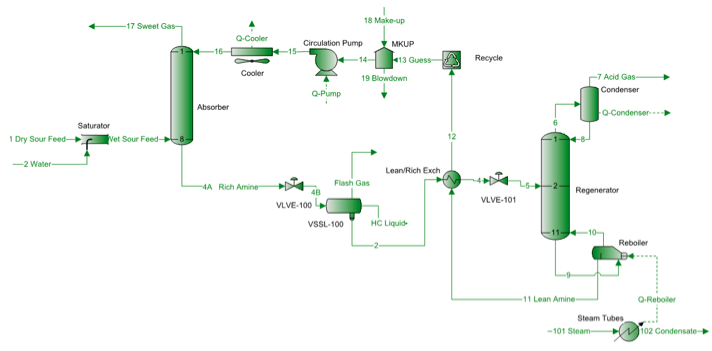

A simplified process flow diagram for the case studied is presented in Figure 1 [1].

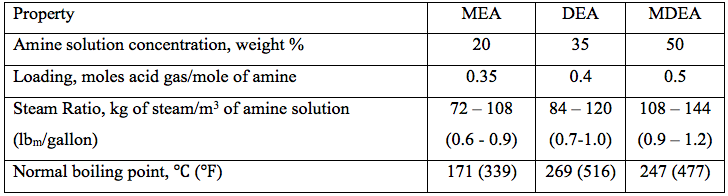

Table 2. Specified amine concentration, target rich solution acid gas loading, and steam ratios [6

”] Results and Discussions:

Results and Discussions:

Based on the description and specifications presented in the previous section, the process flow diagram in Figure 1 was simulated by ProMax [5]. The simulation was performed for steam ratios presented in Table 2. For each steam ratio and each amine, the H2S and CO2 concentration in the sweet gas, lean amine circulation rate, reboiler duty, and the amine make up to compensate the losses due to vaporization from top of contactor and regenerator columns, and flashed gas in the separator are calculated. The variation of these properties as a function of steam rate is presented in Figures 2 through 8.

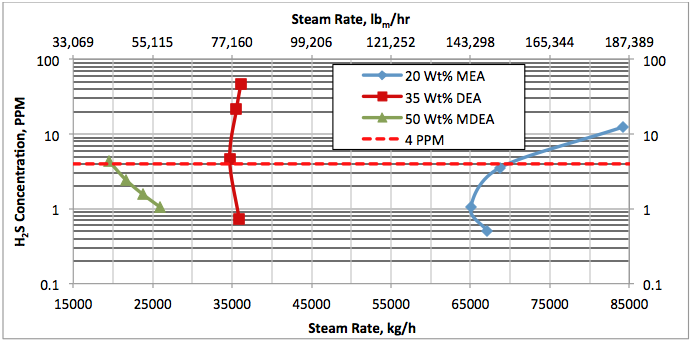

Figure 2. Sweet gas H2S content vs steam rate

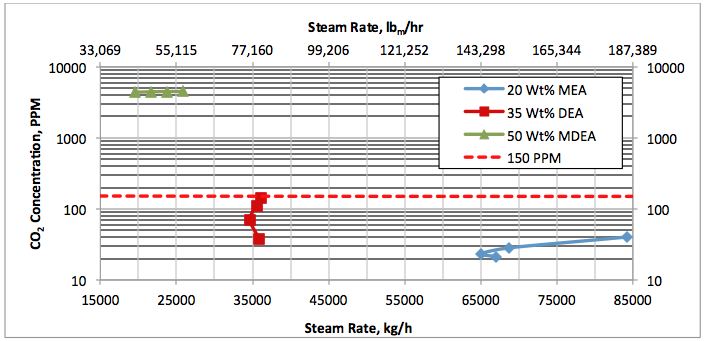

Figure 3. Sweet gas CO2 content vs steam rate

Figures 2 and 3 present the variation of H2S and CO2 concentration in the sweet gas stream as a function of steam rate for MEA, DEA, and MDEA. Figure 2 also indicates that the minimum steam rate to achieve common pipeline specification of H2S concentration of 4 PPM. It should be noted that for the same H2S concentration in the sweet gas, MDEA requires the lowest steam rate. Figure 3 indicates that both MEA and DEA do much better at removal of CO2 than MDEA. Because MDEA requires the lowest steam rate, it is a preferred amine for selective removal of H2S.

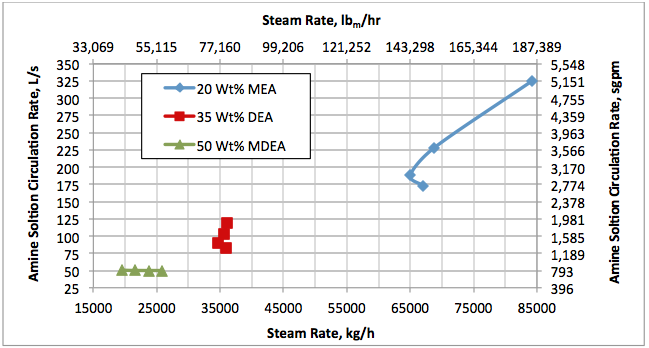

The required amine circulation rate as a function of steam rate is presented in Figure 4 for MEA, DEA, and MDEA. Figure 4 indicates that MDEA requires the smallest circulation rate for regeneration. In addition, the MDEA circulation rate is much lower than that of the other two amines. This is because MDEA has a much higher concentration (smaller amount of water) and can have higher maximum allowable acid gas loading in the rich solution (Refer to Table 2) compare to MEA and DEA.

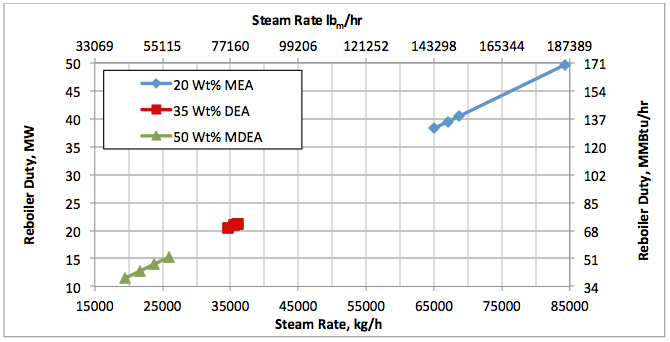

The required reboiler duty as a function of steam rate is presented in Figure 5 for MEA, DEA, and MDEA. Figure 5 indicates that MDEA requires the smallest heat duty due to its very low circulation rate.

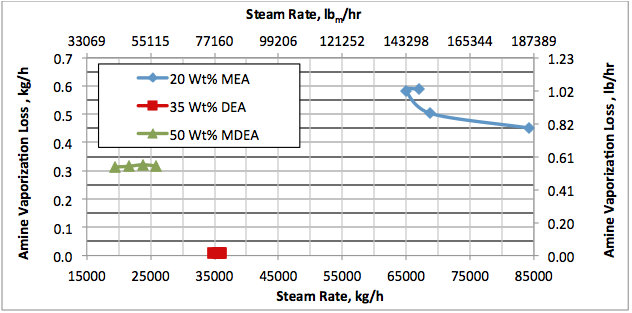

Figure 6 presents the amine make up as a function of steam rate for the three amines. This figure indicates that MEA has the highest and DEA the lowest vaporization loss. MDEA loss is between MEA and DEA because the normal boiling point of MDEA is between that of MEA and DEA (refer to Table 2). It should be noted that this loss does not include entrainment (mechanical) from the top of contactor. Amine vaporization loss from top of the regenerator column was practically zero for all three amines. The mechanical (entrainment) loss is normally much higher than vaporization loss.

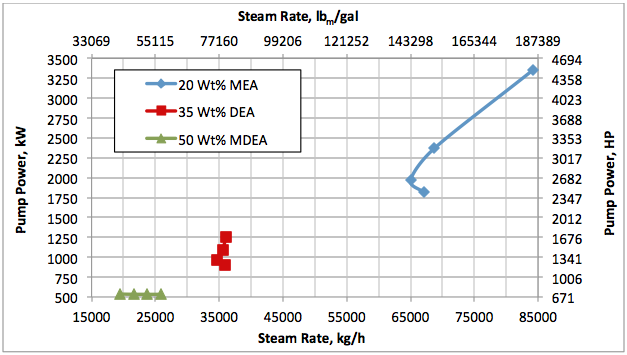

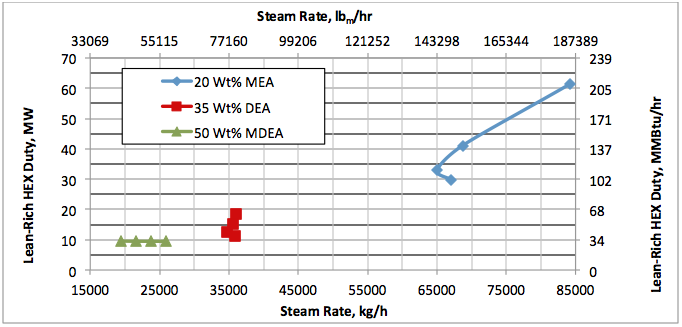

Figures 7 and 8 present the required pump power and lean-rich amine heat exchanger duty as a function of steam rate for the three amines, respectively. These two figures also indicate the MDEA requires the lowest pump power and heat exchanger duty due to its lowest circulation rate.

Figure 4. Circulation rate vs steam rate

Figure 5. Reboiler duty vs steam rate

Figure 6. Total amine vaporization loss vs steam rate

Figure 7. Pump power vs steam rate

Figure 8. Lean-Rich HEX duty vs steam rate

Optimized Condition

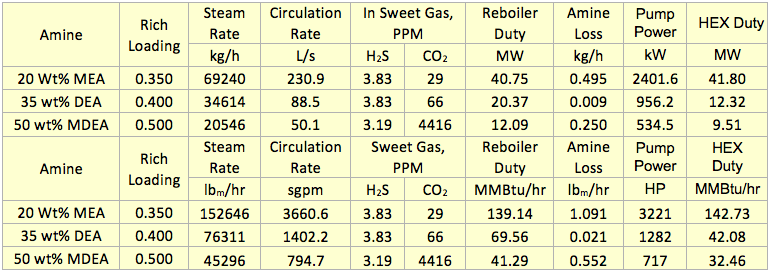

For each amine the optimized/minimum steam rate to meet sweet gas H2S content of 4 PPM was determined and the corresponding parameters are calculated and reported in Tables 3 and 4.

Table 3. Optimized parameters for three amines

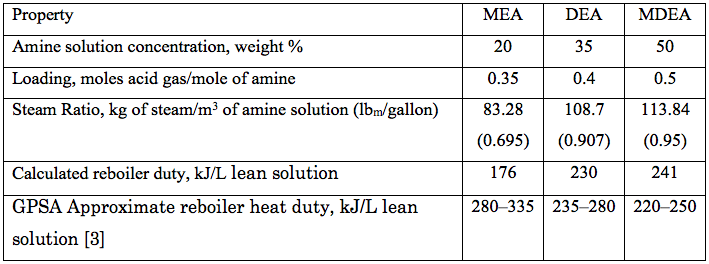

Table 4 indicates that the optimized reboiler duty for DEA and MDEA are within the approximate guideline provided by the GPSA data book [3]; however, MEA reboiler duty is below the approximate guideline. According to the GPSA data book, reboiler duty varies with regenerator overhead reflux ratios, rich solution feed temperature to regenerator and reboiler temperature. In this case the same values of the above mentioned variables were used for the three amines. For a detailed comparison, for each amine the optimized variables should be selected.

Table 4. Comparison of reboiler duty with GPSA data book [3

Conclusions:

Based on the results obtained for the case study considered in this TOTM, the following conclusions can be made:

- MDEA is selective in removal of H2S and allows some of the CO2 to slip through (Figures 2 and 3).

- For a specified H2S content in the sweet gas, regeneration of MDEA requires:

- the lowest steam rate (reboiler duty).

- the lowest pump power.

- the lowest lean-rich HEX duty.

- MDEA vaporization loss is between MEA and DEA.

- Amine vaporization loss from the top of the regenerator column is practically zero.

- The entrainment (mechanical) losses are much greater than the vaporization losses

To learn more about similar cases and how to minimize operational problems, we suggest attending our G6 (Gas Treating and Sulfur Recovery), G4 (Gas Conditioning and Processing), PF81 (CO2 Surface Facilities), PF4 (Oil Production and Processing Facilities), and PL4 (Fundamentals of Onshore and Offshore Pipeline Systems) courses.

John M. Campbell Consulting (JMCC) offers consulting expertise on this subject and many others. For more information about the services JMCC provides, visit our website at www.jmcampbellconsulting.com, or email us at consulting@jmcampbell.com.

By: Dr. Mahmood Moshfeghian

Reference:

- Maddox, R.N., and Morgan, D.J., Gas Conditioning and Processing, Volume 4: Gas treating and sulfur Recovery, Campbell Petroleum Series, Norman, Oklahoma, 1998.

- Campbell, J.M., Gas Conditioning and Processing, Volume 2: The Equipment Modules, 9th Edition, 1st Printing, Editors Hubbard, R. and Snow –McGregor, K., Campbell Petroleum Series, Norman, Oklahoma, 2014.

- GPSA Engineering Data Book, Section 21, Volume 2, 13th Edition, Gas Processors and Suppliers Association, Tulsa, Oklahoma, 2012.

- Moshfeghian, M., Bell, K.J., Maddox, “Reaction Equilibria for Acid Gas Systems, Proceedings of Lawrence Reid Gas Conditioning Conference, Norman, Oklahoma, 1977

- ProMax 3.2, Bryan Research and Engineering, Inc., Bryan, Texas, 2014.

- Sour Gas Processing Training Manual, Bryan Research and Engineering, Inc., Bryan, Texas, 2014.

Nice blog sir ,

I have few questions tho

i dont quite understand how in figure 2 for MEA the H2S concentration increases as we increase the steam ratio ?

i suppose that if we increase steam ratio the lean amine H2S content will be lower which means the H2S in sweet gas will be lower too ?

The behavior of MEA in all charts is quite weird , i hope you would explain it in specific , Thanks !

dear sir ,

why we keep some ppm h2s(200ppm h2s)in lean amine after rich amine processing?

why we not keep 0 ppm h2s in lean amine?

Sir,

your gas articles are very educative. Kindly send me the edition of April to date 2014.

Thank

I am new here. I want to receive new post.

Everyone loves what you guys are usually up too.

This sort of clever work and reporting! Keep up the

amazing works guys I’ve included you guys to my blogroll.

Dear Dr. Mahmood,

This is another very interesting and practical post. May I know the steam condition that you use in the simulation? Thank you for the post.

thank you for u

but i want ask about the loss of DEA when the concentration is in the range 7:10 wt% and there is not filteration and flash drum

[…] July 2014 TOTM compared the performance of monoethanolamine (MEA), diethanolamine (DEA) and methydeithanolamine […]

[…] and determined the quantitative traces of methanol ending up in the TEG dehydrated gas [3]. The July 2016 TOTM considered the presence of methanol in the sour gas of a sweetening unit and determined the […]

[…] Moshfeghian, M., July 2014 tip of the month, PetroSkills – John M. Campbell, […]

[…] Moshfeghian, M., July 2014 tip of the month, PetroSkills – John M. Campbell, […]