In a previous “Tip of the Month” we briefly discussed the need for understanding a phase diagram in a gas processing system. We also defined the areas of a light mixture phase envelope and the terms necessary to “talk intelligently” about the shape of a mixture phase diagram. This allowed us to look at the methods of calculation and their limitations in another tip and eventually defined our areas of risk in the operation or design of a facility based on the phase diagram.

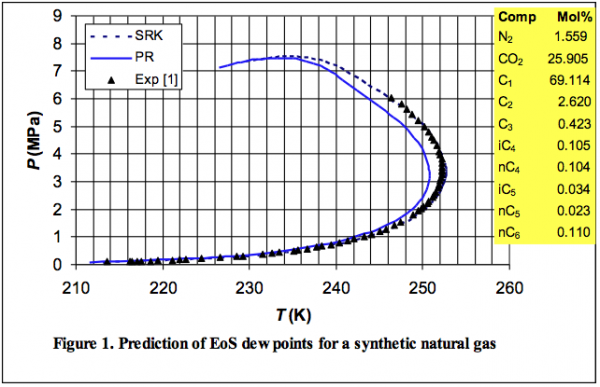

In this Tip we will explain how a phase envelope is generated and what factors affect the shape and accuracy of a phase envelope. There are two methods of generating a phase envelope: a) by conducting a series of bubble point and dew point measurements in a PVT laboratory b) Using a cubic EoS such as SRK or PR and performing a series of bubble point and dew point calculations. The triangle symbols in Figure 1 present a phase envelope measured in a laboratory for a synthetic natural gas.

For the same mixture, we used GCAP for Volume 2 of Gas Conditioning and Processing Software to generate the phase envelope using SRK and PR EoSs. The dashed line represents the SRK EoS and the solid line represents the PR EoS. As can be seen, for this case the SRK EoS gives a perfect match with the experimentally measured dew point curve but PR predicts a lower cricondentherm point. The built in and in–house binary interaction parameters for SRK and PR were used to generate these two diagrams; however, an experienced engineer is able to produce a close match for either of these two EoSs by tuning the binary interaction parameters and/or heavy end properties.

The best practical method for generating an accurate phase envelope by any commercial software is to utilize a limited number of VLE measurements and tune one or more properties of the heavy ends (C7+). In other words, we suggest using combination of methods “a” and “b”.

For real natural gas mixtures, the components and composition of the heavy ends are not well defined and laboratory measurements are not accurate enough. Therefore, different techniques as described in the literature and Volume 3 of Gas Conditioning and Processing are used to properly characterize the heavy ends resulting in an overall acceptable match.

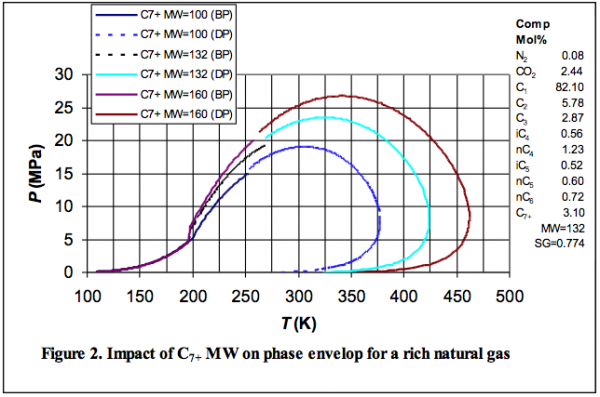

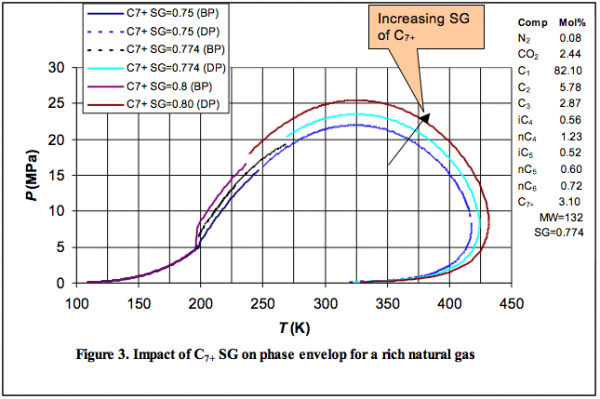

Since the laboratory reported values of molecular weight (MW) and specific gravity (SG) of C7+ are questionable, in the proceeding section we will demonstrate the impact of these two properties on the shape of overall phase envelope.

Figure 2 presents the impact of molecular weight of C7+ on the phase envelope of a rich natural gas mixture. As the C7+ molecular weight increases, the cricondentherm temperature and cricondenbar pressure will increase and the two phase region expands.

Figure 3 shows that as the C7+ specific gravity increases, the cricondentherm temperature and cricondenbar pressure will also increase and the two phase region expands.

From these two diagrams, one can see that improper characterization of heavy ends may result in a bad design or troublesome operation (e.g. designing a dry gas pipeline instead of two phase gas-liquid flow).

In the next tip of the month we will demonstrate how to tune computer software to generate proper and relatively accurate phase envelopes.

By: Dr. Mahmood Moshfeghian

Reference:

1. C. Jarne, S. Avila, S. T. Blanco, E. Rauzy, S. Otin, I. Velaso, Ind. Eng. Chem. Res. 43 (2004) 209-217.

I’m now not sure thee place you’re getting your info, however great topic.

I needs to spend some time finding out more or figuring

out more. Thak you for excellent info I was in search of this information for my mission.

I just gone through the Article. It explained everything what I was looking for. Very powerful information.

Awesome site you have here but I was wanting to know if you knew of any forums that cover the same topics talked about here? I’d really like to be a part of group where I can get suggestions from other experienced individuals that share the same interest. If you have any recommendations, please let me know. Thanks!

Do you mind if I quote a few of your posts as long as I provide credit and sources back to your website? My blog site is in the exact same area of interest as yours and my visitors would certainly benefit from some of the information you present here. Please let me know if this alright with you. Cheers!

Absolutely composed articles , regards for information .

Do you mind if I quote a few of your articles as long as I provide credit and sources back to your site? My blog site is in the very same area of interest as yours and my users would really benefit from some of the information you provide here. Please let me know if this alright with you. Cheers!

I delight in, lead to I found just what I was having a look for. You have ended my 4 day lengthy hunt! God Bless you man. Have a great day. Bye

I intended to compose you one very little word to be able to thank you over again for your incredible basics you have discussed on this website. This has been really tremendously open-handed with people like you to present publicly just what a number of people would have marketed as an electronic book to get some cash for themselves, primarily considering the fact that you could have done it in case you wanted. The pointers additionally acted to be a easy way to understand that other people online have similar keenness like my very own to know the truth many more pertaining to this matter. I know there are numerous more pleasant sessions up front for folks who find out your website.

Unquestionably believe that which you said. Your favorite justification appeared to be on the net the easiest thing to be aware of. I say to you, I certainly get annoyed while people consider worries that they plainly don’t know about. You managed to hit the nail upon the top and defined out the whole thing without having side effect , people could take a signal. Will probably be back to get more. Thanks

I¡¦ve recently started a website, the info you provide on this site has helped me greatly. Thanks for all of your time & work.