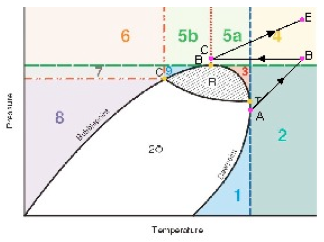

In a previous “Tip of the Month” we briefly discussed the problems of how to “name” the various regions of the phase diagram. To decide if this “naming game” can be a problem, look at Figure 1.

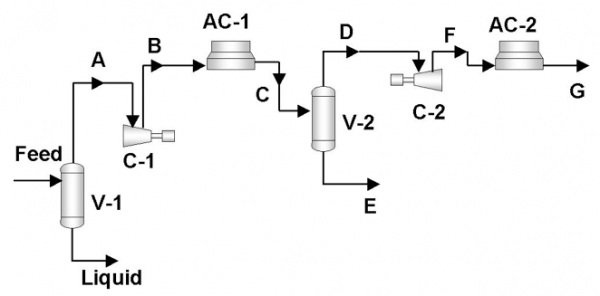

This is a typical two-stage compressor system with intercoolers. This particular system however is being used to compress gas to a pressure above the cricondenbar of the gas for “dense phase” transportation. Note that the streams are only labeled with letters because I used numbers on the phase diagram. As a “process engineer” I find it difficult to discuss streams with out seven digit numbers identifying them.

Point A is easily “defined” as a saturated vapor. Point B will be superheated vapor or possibly dense phase. Point C might be 2 phase, super heated vapor, dense phase, or liquid phase. From an equipment point of few in all cases but the two-phase case, separator V-2 is not needed, in theory. In practice, we would always install V-2 as very minor changes in temperature or pressure can sometimes dramatically change the quantity of liquid in stream E.

For computer simulation of this process, the designation of the “phases” of stream C becomes quite important. Assuming the simulator has the ability to calculate Vapor-Liquid equilibrium properly, the two-phase case is the only case where the simulator can be trusted to give the proper duty requirements for compressor C-2.

Figure 2 is the “generic” phase diagram for a light mixture that we previously discussed. The general areas are: to the left of the phase diagram – liquid; area to the right of the phase diagram – vapor; the area inside the phase diagram – two phase; and the area above the phase diagram – dense phase.

My personal preferences for the sub areas are listed below:

Area 1 – Vapor

Area 2 – Vapor

Area 3 – Vapor

Area 4 – Vapor

Area 5 – Dense phase

Area 6 – Liquid

Area 7 – Liquid

Area 8 – Liquid

Area 9 – Vapor

The stream labels from figure 1 are plotted on the diagram. Note this assumes that the phase diagram represents the composition of the gas leaving separator V-1.

If stream C is “named” vapor by the simulator, then most computer simulations will properly calculate the power requirements of C-2. If stream C is “named” liquid by the simulation program then C-2 will have no flow through it. The program will either “fail” or worse yet give meaningless answers. Worse yet some simulators identify point C as two-phase with an arbitrary split between the flow rates of streams D and E.

The current trend in commercial simulators is to always “give an answer” no mater how “stupid the question is.” Most simulators will generally give warnings when calculating a “meaningless” answer, but with the current shortage of engineers, the chances of these being identified are fairly small.

This is a simple example of how “naming” can get you in trouble. There are many more that occur subtly inside simulations. Many of these errors go undetected because the program is quite “happy” with whatever phase it calculates.

For examples of how the choice of the name might be important in your process simulation calculations, contact JMC@jmcampbell.com for test simulations that you can use with your process simulator.

At a future date we will discuss the meaning of “condensate” and why this is so politically important even today.

In the meantime Chapter 4 and 5 of Volume I and chapter 15 of Volume II of Gas Conditioning and Processing and Chapter discusses these topics in more detail.

The stream labels from figure 1 are plotted on the diagram. Note this assumes that the phase diagram represents the composition of the gas leaving separator V-1.

WHAT If stream C is “named” vapor by the simulator, then most computer simulations will properly calculate the power requirements of C-2. If stream C is “named” liquid by the simulation program then C-2 will have no flow through it. The program will either “fail” or worse yet give meaningless answers. Worse yet some simulators identify point C as two-phase with an arbitrary split between the flow rates of streams D and E.

The current trend in commercial simulators is to always “give an answer” no mater how “stupid the question is.” Most simulators will generally give warnings when calculating a “meaningless” answer, but with the current shortage of engineers, the chances of these being identified are fairly small.

This is a simple example of how “naming” can get you in trouble. There are many more that occur subtly inside simulations. Many of these errors go undetected because the program is quite “happy” with whatever phase it calculates.

For examples of how the choice of the name might be important in your process simulation calculations, contact JMC@jmcampbell.com for test simulations that you can use with your process simulator.

At a future date we will discuss the meaning of “condensate” and why this is so politically important even today.

In the mean time Chapter 4 and 5 of Volume I and chapter 15 of Volume II of Gas Conditioning and Processing and Chapter discusses these topics in more detail.

By: Dr. Larry L. Lilly

I would like to thnkx for the efforts you’ve put in writing this website. I’m hoping the same high-grade site post from you in the upcoming as well. Actually your creative writing abilities has encouraged me to get my own site now. Actually the blogging is spreading its wings quickly. Your write up is a good example of it.