In this Tip of The Month (TOTM), the effect of striping gas rate and TEG circulation ratio on the still column top temperature for regeneration of rich triethylene glycol (TEG) is investigated. Specifically, this study focuses on the variation of still column top temperature with reboiler pressure, TEG circulation ratio and stripping gas rate. By performing a rigorous computer simulation of TEG regeneration at reboiler pressures of 110.3 kPaa (16 psia) and 524.1 kPaa (76 psia), two charts for quick determination of still column top temperature needed for facilities type calculations are developed. In addition, the effect of theoretical number of trays in the stripping gas section is studied.

Computer Simulation Results:

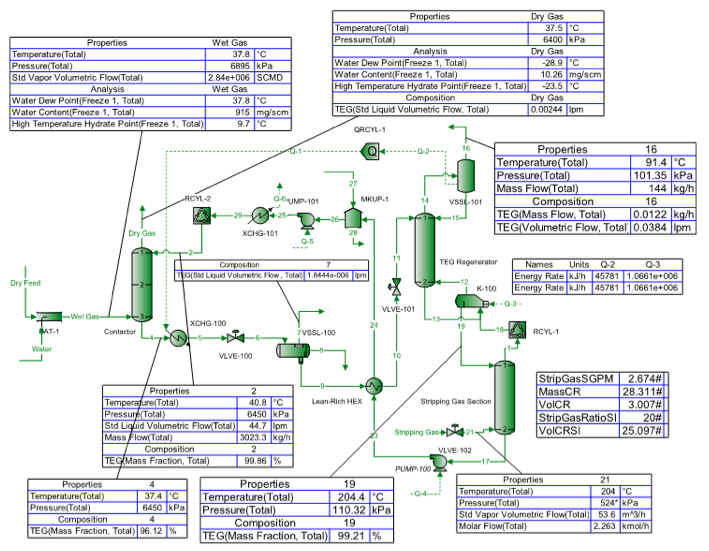

In order to study the impact of stripping gas rate and TEG circulation rate on the still column top temperature, the TEG dehydration process was simulated using ProMax [1] software with its Soave-Redlich-Kwong (SRK) [2] equation of state (EOS). The process flow diagram used for these simulations is shown in Figure 1.

The water-saturated gas with a water content of 915 mg/std m3 (57 lbm/MMSCF) enters the bottom of the contactor column at 37.8°C (100°F) and 6895 kPaa (1000 psia) at a rate of 2.835×106 std m3/d (100 MMSCFD). The contactor column has three theoretical trays. The lean TEG solution enters at the top of the contactor column and flows down in the column. As shown in Figure 1, the water content of the dried gas is 10 mg/std m3 (0.63 lbm/MMSCF). The rich TEG solution contains 96.1 mass percent TEG entering the still column at 100°C (212°F) and 515 kPaa (74.7 psia). The reboiler temperature was set at 204.4°C (400°F) and boil-up ratio of 0.1 (molar bases). Two theoretical trays in the regenerator (still) column (NR = 2) and two theoretical trays (NS = 2) in the striping gas section were specified. The striping gas enters the bottom of the stripping gas section at 204°C (399°F) and 524 kPaa (76 psia). Methane was used for the stripping gas at a rate of 56.3 std m3/h (1893 scf/hr). The regenerated lean solution contains 99.6 mass percent TEG and the ratio of stripping gas to lean TEG liquid volume rates is 20 std m3 of gas/std m3 of lean TEG solution (2.67 scf/sgal) or a mass ratio of 28.3. The regenerator (still) top temperature is 91.4°C (196.5°F). If the same stripping gas was sparged directly into the reboiler (NS = 0, no stripping gas section), with everything else remaining the same, the regenerated solution contains 99.2 mass percent TEG and the regenerator column top temperature remains practically the same and is 91.1°C (196°F). For the above case the number of theoretical trays in the still column is increased from 2 to 3 (NR = 3); the lean TEG concentration increased slightly from 99.6 to 99.8 mass percent but the regenerator column top temperature remained the same.

Using a similar set up as is shown in Figure 1, several simulations were performed for a range of stripping gas rates, for NR=2, NS=0 and for two reboiler pressures of 110.3 and 524 kPaa (16 and 76 psia) and temperature of 204.4°C (400°F). The results of these simulation runs are presented in Figures 2 to 5.

Figure 1. Sample results using ProMax [1] for TEG dehydration with reboiler P=110.3 kPaa (16 psia) with NR=2 and NS=2

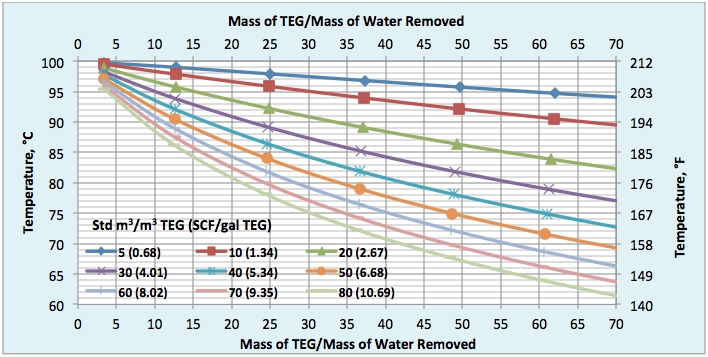

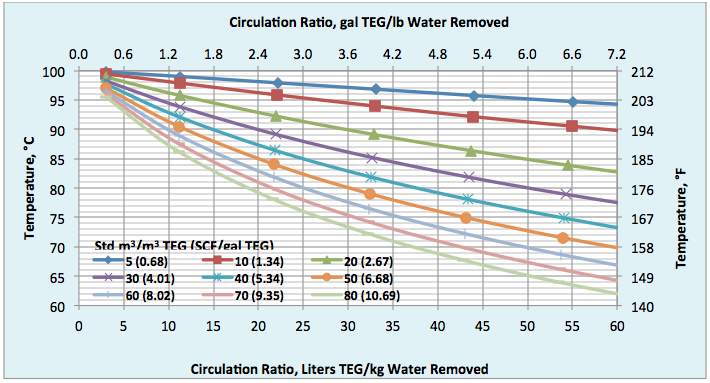

Figures 2 presents the variation of still column top temperature with circulation ratio (mass basis) and stripping gas rate at top pressure of 101.3 kPaa (14.7 psia) and reboiler pressure of 110.3 kPaa (16 psia) operating at 204.4°C (400°F).

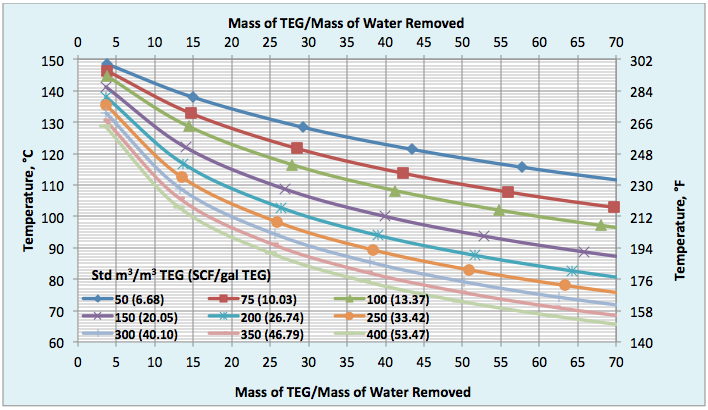

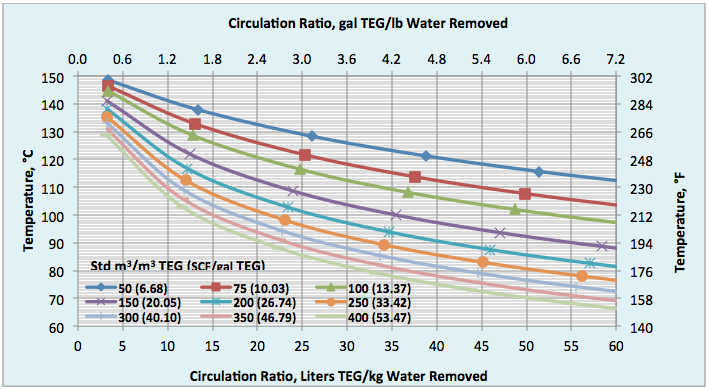

As was discussed in the August 2013 TOTM, regeneration of TEG at higher reboiler pressure has several advantages such as preventing the emission of harmful contaminants like benzene, toluene, ethylbenzene, xylenes (BTEX), and hydrogen sulfide to the environment [3]. Therefore, similar diagrams as shown in Figure 2 were generated for top pressure of 515.2 kPaa (74.7 psia) and reboiler pressure of 524.1 kPaa (76 psia) at 204.4°C (400°F). Figure 3 presents the variation of still column top temperature for such a high reboiler pressure.

Fig 2. Variation of still column top temperature with circulation mass ratio and stripping gas rate at top P=101.3 kPaa (14.7 psia) and reboiler P=110.3 kPaa (16 psia) at 204.4°C (400°F)

Fig 3. Variation of still column top temperature with circulation msss ratio and stripping gas rate at top P=515.2 kPaa (74.7 psia) and reboiler P=524.1 kPaa (76 psia) at 204.4°C (400°F)

Figures 2 and 3 can be used for a quick determination of the still column top temperature for a given stripping gas rate and TEG circulation ratio either at low or high reboiler pressure. The two reboiler pressures selected in this study are typical operating pressures. For generation of data for Figures 2 and 3, the stripping gas was sparged directly into the reboiler; therefore, the number of theoretical trays for stripping gas section is zero (NS=0). The corresponding figures in terms of TEG circulation volume ratio are presented in the Appendix (Figures 2A and 3A).

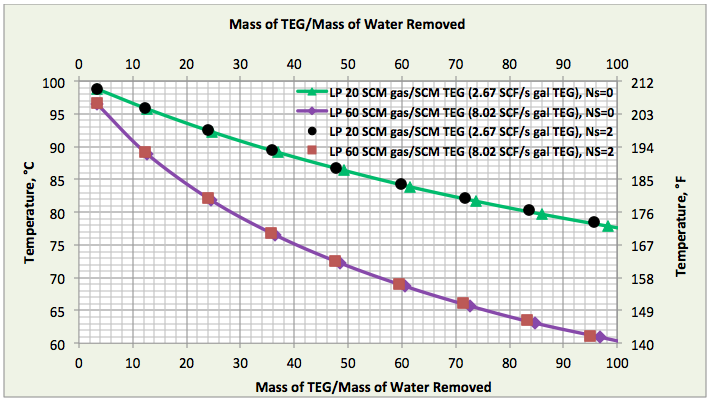

Generally, either 0, 1, or 2 theoretical trays in the stripping gas section is used. In order to investigate the effect of the number of theoretical trays in the stripping gas section (NS) on the still column top temperature, simulations were performed for the cases of NS=0 and NS=2 for two constant stripping gas rates.

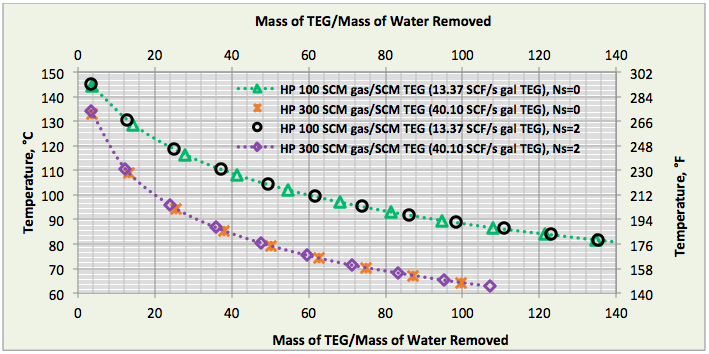

Figures 4 and 5 present the results of these simulations for low and high reboiler presssures of 110.3 kPaa (16 psia) and 524.1 kPaa (76 psia), respectively. The reboiler temperature for all cases was set at 204.4°C (400°F).

Figures 4 and 5 clearly indicate that the still column top temperature is independent of the number of theoretical trays in the stripping gas section. Therefore, Figures 2 and 3 can be used for any number of theoretical trays in the stripping gas section.

Fig 4. Effect of the number of theoretical trays (NS) on the still column top temperature at various circulation ratio and stripping gas rate at top P=101.3 kPaa (14.7 psia) and reboiler P=110.3 kPaa (16 psia) at 204.4°C (400°F)

Fig 5. Effect of the number of theoretical trays (NS) on the still column top temperature at various circulation ratio and stripping gas rates at top P=515.2 kPaa (74.7 psia) and reboiler P=524.1 kPaa (76 psia) at 204.4°C (400°F)

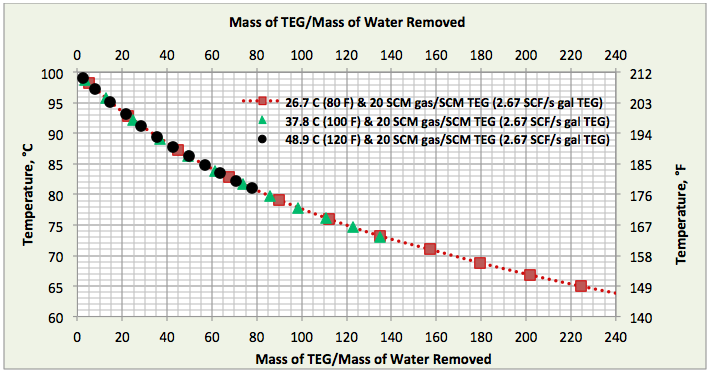

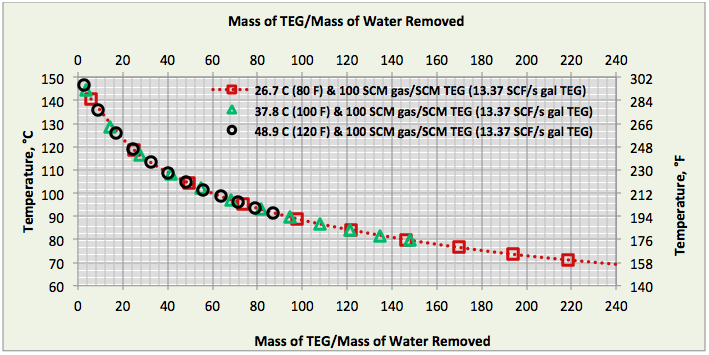

Similar study also showed that the feed gas temperature to the contactor column has no effect on the still column top temperature. The results of this study are shown in Figures 6 and 7 of the Appendix.

Conclusions:

In this TOTM, the effect of circulation ratio, stripping gas rate, theoretical number of trays, and the feed gas temperature to the contactor column on the still column top temperature for regeneration of TEG concentration at low and high reboiler pressure operating at 204.4°C (400°F) was studied. Two charts for a quick determination of the still column top temperature at a specified stripping gas rate and circulation ratio to achieve a desired level of lean TEG concentration were prepared and presented in Figures 2 through 3 (see the corresponding figures in the Appendix). These charts are based on the rigorous calculations performed by computer simulations and can be used for facilities type calculations for evaluation and trouble shooting of an operating TEG dehydration unit. In addition, the following observations were made:

- The still column top temperature is independent of the number of theoretical trays in the stripping gas section (NS) and feed gas temperature to the contactor column.

- As the stripping gas rate increased, the still column top temperature decreased.

- As the TEG circulation ratio increased, the still column top temperature decreased.

- Pressurized reboiler results in much higher still column top temperature than the atmospheric reboiler.

To learn more, we suggest attending our G40 (Process/Facility Fundamentals), G4 (Gas Conditioning and Processing), G5 (Gas Conditioning and Processing-Special), and PF81 (CO2 Surface Facilities), PF4 (Oil Production and Processing Facilities), courses.

John M. Campbell Consulting (JMCC) offers consulting expertise on this subject and many others. For more information about the services JMCC provides, visit our website at www.jmcampbellconsulting.com, or email us at consulting@jmcampbell.com.

By: Dr. Mahmood Moshfeghian

References:

- ProMax 3.2, Bryan Research and Engineering, Inc., Bryan, Texas, 2013.

- Soave, G., Chem. Eng. Sci. Vol. 27, No. 6, p. 1197, 1972.

Moshfeghian, M., http://www.jmcampbell.com/tip-of-the-month/2013/08/teg-dehydration-how-does-the-stripping-gas-work-in-lean-teg-regeneration/, Tip of the Month, August 2013.

Appendix

Fig 2A. Variation of still column top temperature with circulation volume ratio and stripping gas rate at top P=101.3 kPaa (14.7 psia) and reboiler P=110.3 kPaa (16 psia) at 204.4°C (400°F)

Fig 3A. Variation of still column top temperature with circulation volume ratio and stripping gas rate at top P=515.2 kPaa (74.7 psia) and reboiler P=524.1 kPaa (76 psia) at 204.4°C (400°F)

Fig 6. Variation of still column top temperature with circulation mass ratio and feed gas temperature to the contactor column at a specified stripping gas rate at top P=101.3 kPaa (14.7 psia) and reboiler P=110.3 kPaa (16 psia) at 204.4°C (400°F)

Fig 7. Variation of still column top temperature with circulation mass ratio and feed gas temperature to the contactor column at a specified stripping gas rate at top P=515.2 kPaa (74.7 psia) and reboiler P=524.1 kPaa (76 psia) at 204.4°C (400°F)

Very good study , i have one comment as below:

Fig-4 and Fig -5 that explain the reboiler pressure effect on still top column teperature may need to be operated with the same stripping gas flow ration with TEG rate for better evalution , what i observed that LP reboiler fig-4 is running with low stripping gas flow ration than HP reboiler , for the sake of good comparizon better to fix the stripping gas rate / ratio for both cases to see the reboiler pressure effect.

[…] M., http://www.jmcampbell.com/tip-of-the-month/2013/11/estimating-still-column-top-temperature-in-teg-de…, Tip of the Month, November […]

Dear Dr. Mahmood Moshfeghian,

Thank you for providing useful information.

Can you please suggest the effect of Stripping gas pressure on TEG looses and Purity of TEG.

What would be the recommended supplied pressure of stripping gas to stripping column.

Thanks

Regards

Srinivas Ch

Sweet website , super style and design , really clean and use pleasant.

Have you ever thought about writing an e-book or guest authoring on other websites?

I have a blog based on the same information you discuss and

would really like to have you share some stories/information.

I know my viewers would appreciate your work. If you’re even remotely interested, feel free to

shoot me an e-mail.

Thanks a bunch for sharing this with all people you actually know what you’re speaking approximately! Bookmarked. Please additionally visit my web site =). We may have a hyperlink change arrangement between us!

Hi Doctor

Will you tell me based on your experience;

How lower temperature of the feed gas, TEG can treat?

Feed gas temperature of 15deg.c near the hydrate temperature can be treated?

Best Regards

nice

My colleagues were searching for VA 21-674 earlier today and learned about a great service that hosts lots of form templates . If people have been needing VA 21-674 too , here’s

https://goo.gl/HlLWnB.[…] M., http://www.jmcampbell.com/tip-of-the-month/2013/11/estimating-still-column-top-temperature-in-teg-de…, Tip of the Month, November […]