The design or specified minimum temperature approach of a heat exchanger has a significant effect on the total heat transfer area required. As a result, the specified temperature approach (TA) should be carefully considered in the heat exchanger specification process as this is one of the primary factors in heat exchanger capital cost. Depending upon heat exchanger service and type, there are typical economic minimum temperature approaches which have been determined from industry experience.

Continuing the April 2019 [1] Tip of The Month (TOTM), this tip investigates the impact of the TA on the performance of a mechanical refrigeration plant with mono-ethylene glycol (EG or MEG) injection for hydrocarbon dew point (HCDP) control. Specifically, how the TA impacts the gas-gas heat exchanger, chiller duties and the operation of the mechanical refrigeration system will be investigated and reported. In addition, the annualized CAPEX, Annual OPEX (Energy Cost) and annual total cost as a function of the gas-gas heat exchanger (HX) hot end TA will be reported.

The details of a mechanical refrigeration plant with MEG injection and regeneration system are given in Chapters 6, 15 and 18 of the Gas Conditioning and Processing, Volumes 1 and 2 [2, 3], respectively.

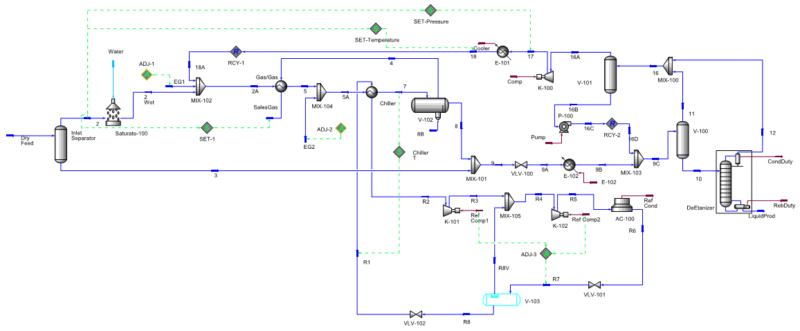

Figure 1 presents the process flow diagrams for a typical HCDP control plant using mechanical refrigeration with MEG injection system. This figure is similar to the Apr 2019 TOTM [1] which utilizes a flash tank economizer with two stages of compression. In this tip, all simulations were performed with UniSim Design R443 software [4] using the Peng-Robinson equation of state.

Figure 1. Process flow diagrams for an HCDP plant using mechanical refrigeration with a flash tank economizer and MEG Injection system

Figure 1. Process flow diagrams for an HCDP plant using mechanical refrigeration with a flash tank economizer and MEG Injection system

Introduction (Extracted from Chapter 12 of Reference [3]):

The surface area of a heat exchanger can be calculated by Equation 1.

(1)

(1)

Where:

A = heat exchanger area in m2 [ft2]

Q = heat transfer rate in kW [Btu/hr]

Uo = overall heat transfer coefficient in W/ (m2 oC) [Btu/(hr-ft2–oF)]

ΔTeff = effective temperature difference oC [oF]

Figure 2 presents a temperature profile as a function of heat transfer in a chiller and a gas-gas HX. In the chiller, the process fluid is partially condensing in the tube side, and pure propane is boiling in the shell side. In the gas-gas HX, the process fluid (stream 5) is partially condensing in the tube side and the gas stream 4 is warming (no phase change) in the shell side.

Figure 2. Effective Temperature Difference Schematics [2]

The only temperatures that can be conveniently measured are at the inlet and outlet of the exchanger. The largest difference on one end of the heat exchanger will be referred to as ΔT1, the smaller ΔT2, which is also called the minimum approach.

Equation 2 provides a simple method for estimating the effective temperature difference (ΔTeff) in the exchanger.

(2)

(2)

Where:

LMTD = log mean temperature difference

ΔTeff = temperature difference corrected for heat exchanger configuration

F = TEMA MTD Correction Factor

ΔT1 = largest ΔT (at one end of the heat exchanger)

ΔT2 = smallest ΔT (at one end of the heat exchanger)

Equation 2 is based on several assumptions. The primary one being that the heating and cooling curves (T vs Q) for the exchanger streams are linear. For multi-component fluids this is true when there is little or no phase change in the exchanger. If you apply this equation, always have a look at the cooling curves to verify this assumption is adequate the application.

Notices in this equation that as ΔT2 (minimum approach) decreases, ΔTeff decreases and the required heat transfer area increases as shown in Equation 1. This increase can be significant as ΔTeff approaches zero. On the other hand, smaller values of ΔT2 in the gas-gas exchanger for a refrigeration plant decreases the utility costs (power and fuel) there is more “free cold energy” transferred in the heat exchanger. For this specific process application (gas-gas exchanger) both effects should be considered in heat exchanger specifications.

Note that the minimum approach may occur at the “hot” end or “cold” end of the exchanger depending on the application. The minimum approach may also occur internally inside the exchanger. Typical economic minimum approaches for various heat exchangers and applications are presented in Table 1.

Table 1. Typical Heat Exchanger Approach Ranges [3]

For compact exchangers, smaller minimum approaches are usually economically justifiable. Compact heat exchangers have a greater surface area per volume than shell and tube heat exchangers. In addition, they have higher fluid velocities, which result in greater overall heat transfer coefficients.

CASE STUDY

Let’s consider the same case presented in Apr 2019 TOTM [1] for a rich gas with the compositions and conditions presented in Table 2 [1]. Based on the reported molecular weight and relative density for the C7+ fraction, Table 3 presents the estimated normal boiling point (NBP), critical properties and acentric factor which, are needed by the equation of state. The objective is to meet a hydrocarbon dew point specification of -20 °C (-4 °F) at about 4000 kPa (580 psia) for the sales gas by removing heat in the “Gas/Gas” heat exchanger (HX) with a hot end TA of 5°C (9°F) and in a propane chiller, 5 °C (-4 °F) TA, and rejecting it to the environment by a propane condenser (AC-100) at 37.8°C (100°F). Pure propane is used as the working fluid in the simulation. The pressure drops in the “Gas/Gas” HX and the propane chiller are assumed to be 34.5 kPa (5 psi).

Table 2. Rich feed gas compositions and conditions

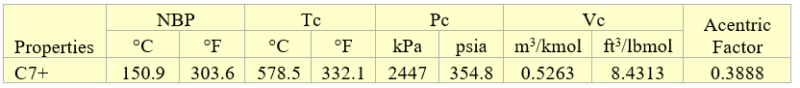

Table 3. Estimated C7+ properties [4]

The feed gas is flashed in the “Inlet Separator” at 30 °C (86 °F) and 4000 kPa (580 psia) to remove any condensate. The “Inlet Separator” vapor (stream 2) is saturated with water by the “Saturate -100” to form stream “2 Wet” upstream of mixing with MEG hydrate inhibitor, stream “EG1” and the recycle stream “18A” from the deethanizer overhead vapor (located at the right-hand side of Fig. 1).

The estimated hydrate formation temperature (HFT) of streams 5 and 7 is 14.7 °C (58.4 °F). The hydrate inhibitor is injected at the inlet of “Gas/Gas” HX by stream “EG1” and at the inlet of the “Chiller” by stream “EG2”. Stream “5” cools to about -8 °C (17.6 °F) and stream “7” cools down to the specified temperature of -20 °C (-4 °F), which is below the HFT of 14.7 °C (58.4 °F). The injection rates of streams “EG1” and “EG2” for 80-weight % lean MEG and water solution are estimated manually or by the Adjust tool of UniSim. A design margin of 1 °C (1.8 °F) HFT below the cold temperature for streams “5” and “7” were assumed.

Assuming a temperature approach of 5°C (9°F) and a 6.9 kPa (1 psi) pressure drop in the propane chiller “Chiller” shell side, the pressure of saturated propane vapor leaving the chiller is 203.3 kPa (29.5 psia), and at a temperature of -25°C (-13°F). Assuming no frictional losses in the suction line to the propane compressors “K-101” and “K-102”, the resulting suction pressure is 203.3 kPa (29.5 psia).

The condensing propane pressure at the specified condenser temperature of 37.8 °C (100 °F) is 1303 kPa (189 psi). The condenser “AC-100” frictional losses, plus the frictional losses in the piping from the compressor discharge to the condenser were assumed to be 34.5 kPa (5 psi); therefore, the discharge pressure of compressor “K-102” is 1338 kPa (194 psia). The compressors interstage pressure was determined by equalizing the power for “K-101” and “K-102”. The compressors adiabatic efficiency was assumed to be 75%.

The cold Stream 7 is flashed in the 3-phase separator “V-102” at -20 °C (-°4F) and 3931 kPa (570 psia). The vapor stream “4” from this cold separator is used to cool down the incoming warm feed gas in the “Gas/Gas” HX. The heavy liquid stream “8B” (rich MEG solution) from the cold separator is regenerated in the regeneration unit (not shown in Fig. 1) and the lean 80 weight % MEG is recycled and used in streams “EG1” and “EG2”. The cold NGL stream “8” (light liquid phase) from the cold separator, “V-102”, is combined with the plant “Inlet Separator” condensate (stream “3”) in the mixer “Mix-101” to form stream “9” at about 5 °C (41 °F) and 3945 kPa (572.2 psia). To prepare the liquid to be fed to the deethanizer, the process specification is to raise the temperature of the NGL product stream “9A” from about -4°C (25°F) and 1535 kPa (222.6 psia) to 20 °C (68 °F) and 1500 kPa (217.6 psia) in “E-102” HX. The process duty and the temperature of the NGL product stream is set by the deethanizer process requirements. The pressure drops in “E-102” HX is 35 kPa (5 psi).

Deethanizer Specifications and Performance:

Like the Apr 2019 TOTM [1], the deethanizer column specifications are:

► To recover 90 mole percent of propane of the feed in the bottom product

► Methane to propane mole ration equal to 5% in the bottom’s product

► Top and bottom pressures are 1450 and 1500 kPa (210.3 and 217.6 psia), respectively

► Number of theoretical stages 12 plus the condenser and reboiler (determined by the material balance and column shortcut calculations)

The deethanizer simulation results are summarized in Table 4.

Table 4. Summary of deethanizer key design parameters

Impact of Gas/Gas HX Hot End Temperature Approach:

The Gas/Gas HX utilizes the cold temperature of stream 4 at -20 °C (-°4F) to cool down stream 2A. The specified temperature approach (TA) sets the sales gas temperature, which is equal to stream 2A temperature minus the TA. Decreasing the hot end TA increases the heat duty of the Gas/Gas HX, which decreases the stream 5 temperature and reduces the required chiller duty. Typically, the Gas/Gas HX removes about 70% of the total required cooling duty to meet the specified sales gas dewpoint temperature. Therefore, the chiller duty decreases resulting in lower compressor power, decreased propane refrigerant circulation rate, and reduced propane refrigerant condenser duty requirements. This tip investigates the impact of the hot end TA for the Gas/Gas HX for a range of 1 to 11 °C (1.8 to 19.8 °F) while keeping the chiller TA constant at 5 °C (9 °F).

Figure 3 presents the impact of TA on the MEG injection rate of streams EG1 and EG2 upstream of Gas/Gas HX and the chiller, respectively. As the hot end TA increases, stream 5 temperature increases but the stream 7 temperature remains constant at the set value; therefore, the HFT depression of stream 5 (d = HFT minus Stream 5 T) decreases and the required MEG injection rate of stream EG1 decreases. However, the MEG injection rate of stream EG2 increases because the total HFT depression temperature (d = HFT minus Stream 7 T) is constant; therefore, the total MEG injection (EG1 + EG2) rate stays the same. The calculated EG1 and EG2 were summed up and presented in Figure 3.

Figure 3. Impact of the temperature approach on the MEG injection rate upstream of Gas/Gas HX (EG1) and chiller (EG2)

Increasing TA causes a decrease in the Gas/Gas-gas HX duty, which results in an increase in the chiller duty because the total cooling duty is constant. As the chiller duty decreases, the compressor power and condenser duty decreases, too. Figures 4 A and B illustrate the impact of TA on the compressor power, Gas/Gas HX, Chiller, and condenser duty in SI and FPS system of units, respectively.

Figure 4A. Impact of the temperature approach on the Gas/Gas HX, chiller and condenser duty, and compressor power

Figure 4B. Impact of the temperature approach on the Gas/Gas HX, chiller and condenser duty, and compressor power

In order to calculate the required surface area of the heat exchangers a design factor of 1.25 and the following overall heat transfer coefficients in W/m2-°C (Btu/hr-ft2-°F) were assumed: Gas/Gas HX = 283 (50), Chiller = 444 (78), and Condenser = 460 (81).

Figure 5 presents the impact of TA on the required surface area of the Gas/Gas HX, chiller and the refrigerant condenser. This figure indicates that the Gas/Gas HX required area is much greater than the chiller and condenser area because it has greater heat duty. Note for TA cases of 1 and 2 °C (1.8 and 3.6 °F) the required surface areas of Gas/Gas HX are greater than 6000 m2 (64,590 ft2); therefore, two HXs of 50% of the required area should be used [5].

Figures 5. Impact of the temperature approach on the Gas/Gas HX, chiller and condenser surface area

The procedure suggested by Hubbard [5] was used to perform the cost analysis. The CAPEX is the sum of the HXs and compressor costs. The HXs cost was estimated based on the size and surface area for the shell and tube types HXs. It is assumed that the maximum shell diameter is 1.97 m (6 ft) and the L/D was 10. For these dimensions, the maximum surface area per shell is about 6000 m2 (64,590 ft2). For TA cases of 1 and 2 oC (1.8 and 3.6 oF), the Gas/Gas HX with an area greater than 6000 m2 (64,590 ft2) two HXs with 50% required area were used. The compressor CAPEX was estimated based on the required power with a design factor of 1.25. Annualized CAPEX cost was estimated based on 5 years recovery. The annual OPEX (energy cost) was estimated based on the compressor power requirement. The total cost is the sum of the annualized CAPEX and annual OPEX (energy cost). These costs are based on a design factor of 1.25. Because total MEG injection rate and deethanizer performance are independent of TA, they were excluded in the cost analysis.

Figure 6 presents the impact of TA on the estimated annualized CAPEX, annual OPEX (energy cost), and the total annual cost. This figure indicates that the optimum TA for the Gas/Gas HX occurs at 3 °C (5.4 °F).

Figures 6. Impact of the temperature approach on the annual OPEX, annualized CAPEX and the total annual cost

SUMMARY

This tip demonstrated the impact of temperature approach (TA) on the trade-off between CAPEX and OPEX for the mechanical refrigeration of a HCDP control plant. The heat exchanger costs are based on rough estimates; therefore, the economic evaluation presented does not represent the actual costs. The Gas/Gas HX areas are extremely large for TA cases of 1 and 2 oC (1.8 and 3.6 oF). It is unlikely that Shell and Tube exchangers of this size could even be manufactured. The Gas/Gas HX CAPEX for the TA cases of 1 and 2 oC (1.8 and 3.6 oF) assumed two exchangers of the 50 % required surface area. If a new mechanical dewpoint facility were built today, it is probably that the Gas/Gas HX and the chiller would almost certainly be a compact heat exchanger, such as a plate-fin or printed circuit. The compact heat exchanger designs have significantly greater surface area per volume than shell and tube heat exchangers which allows them to achieve smaller economic temperature approaches for a given capital cost.

The minimum cost is at 3 ºC (5.4 ºF), which is where we must go to two parallel shells. This makes sense, because here we have a step change in the configuration. When temperature correction factor, F < 0.8, we usually add another shell in series, which may also give step changes. Typically, these exchangers have two or three shells in series at the final configuration.

To learn more about similar cases and how to minimize operational problems, we suggest attending ourG4 (Gas Conditioning and Processing), G5 (Practical Computer Simulation Applications in Gas Processing) and PF42 (Separation Equipment – Sizing and Selection) courses.

By: Mahmood Moshfeghian, Ph.D.

Sign up to receive the Tip of the Month!

References:

1. Moshfeghian, M., http://www.jmcampbell.com/tip-of-the-month/2019/04/Impact-of -liquid-carryover-on-performance-of-refrigeration-system-with-a-flash-tank-economizer/, PetroSkills -John M. Campbell Tip of the Month, April 2019.

2. Campbell, J.M., “Gas Conditioning and Processing, Volume 1: The Fundamentals,” 9th Edition, 3rd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum

3. Campbell, J.M., “Gas Conditioning and Processing, Volume 2: The Equipment Modules,” 9th Edition, 3rd Printing, Editors Hubbard, R. and Snow–McGregor, K., Campbell Petroleum Series, Norman, Oklahoma, PetroSkills 2018.

4. UniSim Design R443, Build 19153, Honeywell International Inc., 2017.

5. Hubbard, R.A., Personal Communication, March 2019.