Problems in meeting sales-gas dew point specifications are not unusual. A facility engineer often suspects separator carryover when trouble-shooting such a plant. Proper sizing of equipment for vapor-liquid separation is essential to almost all processes. The fundamentals of a simple separator design may be extended to several other processes such as fractionation towers, two-phase flow, slug catcher design etc. Many facility operating problems are related to improperly designed or under-sized gas-liquid separators.

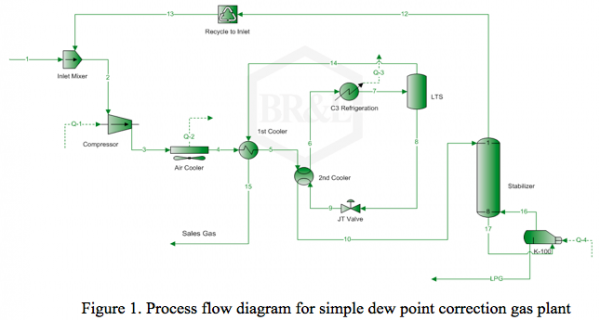

In this Tip of the Month, we will demonstrate the impact of liquid carry over on the sales gas “spec dew point”. Let’s consider the process flow diagram shown in Figure 1 for a simple gas plant. The feed composition and condition are shown in Table 1.

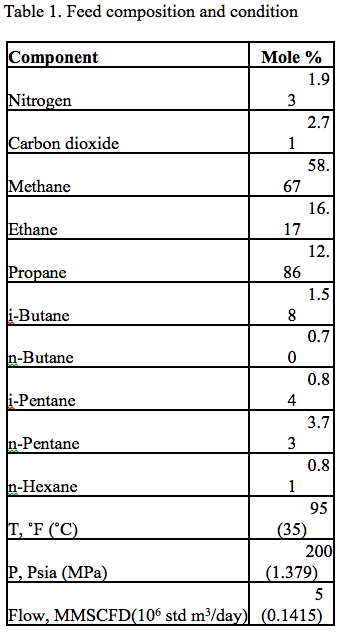

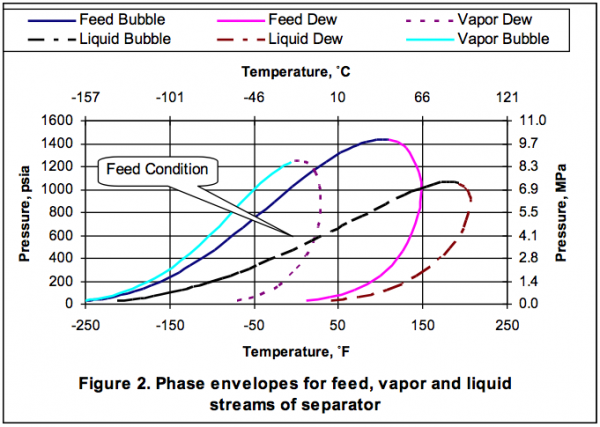

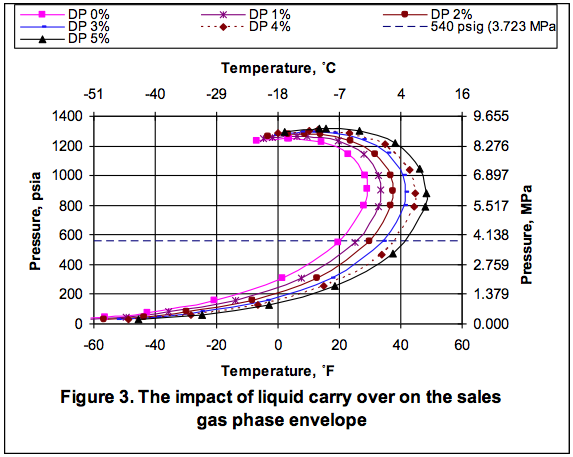

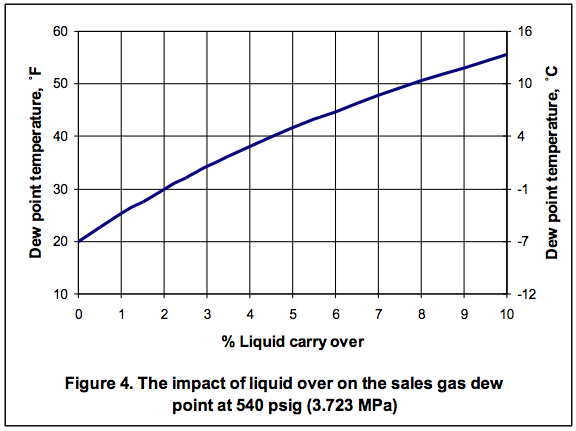

It is desired to process this feed gas to produce a sales gas with a dew point of 20 ˚F (-6.7˚C) at 540 psig (3.723 MPa) The feed gas is mixed with recycle gas from stabilizer, compressed and cooled to 110˚F (43.3˚C) and 555 psig (3.827 MPa), then cooled in the gas-gas exchanger, gas-liquid exchanger and finally in the chiller to 20˚F (-6.7˚C) before entering the separator at 540 psig (3.723 MPa). The phase envelopes for the feed, vapor and liquid streams of the separator are shown in Figure 2. Figure 2 presents the phase behavior of separator if it was operating perfectly, without any liquid carry over or entrainment. In real life, the situation is different and most probably there would be some liquid carry over. In order to show the impact of liquid carry over, we withdraw a small portion of liquid stream from separator and remixed it with the vapor stream and recalculated the dew point temperature. Figure 3 shows how the sales gas dew point curves shift to the right as the percentage of liquid carry over increases. Figure 4 shows the calculated sales gas dew point temperature, at 540 psig (3.723 MPa), as a function of percentage of liquid carry over. It is interesting to note that even a 5% liquid carry over shifts the dew point temperature by more than 20˚F (11˚C) which may results in unexpected large amount of condensate as the gas transported in the pipeline or cause severe damage to the downstream compressor. To learn more about similar cases and how to prevent operational problems such as liquid carry over, we suggest attending our G4 and G5 courses.

By: Dr. Mahmood Moshfeghian

Hello there, I discovered your blog via Google at the same time as

looking for a related matter, your website got here up, it seems to be great.

I’ve bookmarked it in my google bookmarks.

Hello there, simply become alert to your weblog via Google,

and located that it is really informative.

I’m going to watch out for brussels. I’ll be grateful if you happen to proceed this in future.

Numerous people might be benefited from your writing.

Cheers!

Feel free to surf to my web-site – übelkeit (http://nowak4836.blog.com/2014/01/26/ein-schlaglicht-auf-schnelle-beratung-in-ursachen-von-dizziness/)