During the life cycle of a crude oil pipeline the properties of transported oil change, because in gathering systems the produced oils come from different wells. New wells may be added or some wells may go out of production for maintenance and repair. Production rates during the life of wells vary, too. In addition the properties of crude oil change during production. Due to seasonal variation, the average line temperature may also change. As it is shown in the proceeding sections, viscosity of crude oil is a strong function of API gravity and temperature.

In the March 2009 tip of the month (TOTM), procedures for calculation of friction losses in oil and gas pipelines were presented. The sensitivity of friction pressure drop with the wall roughness factor was also demonstrated.

In this TOTM, we will study crude oil °API and the pipeline average temperature and how they effect the pumping requirement. For a case study, we will consider a 160.9 km (100 miles) pipeline with an outside diameter of 406.4 mm (16 in) carrying crude oil with a flow rate of 0.313 m3/s (170,000 bbl/day). The pipeline design pressure is 8.963 MPa (1300 psia) with a maximum operating pressure of 8.067 MPa (1170 psia). The wall thickness was estimated to be 6.12 mm (0.24 in). The wall roughness is 51 microns (0.002 in) or a relative roughness (e/D) of 0.00013. The procedures outlined in the March 2009 TOTM were used to calculate the line pressure drop due to friction. Then assuming 75 % pumping efficiency, the required pumping power was calculated. Since the objective was to study the effect °API and the line average temperature have on the pumping power requirement, we will ignore elevation change. The change in pumping power requirements due to changes in crude oil °API and line average temperature for this case study will be demonstrated.

Case Study 1: Effect of Line Average Temperature (Seasonal Variation)

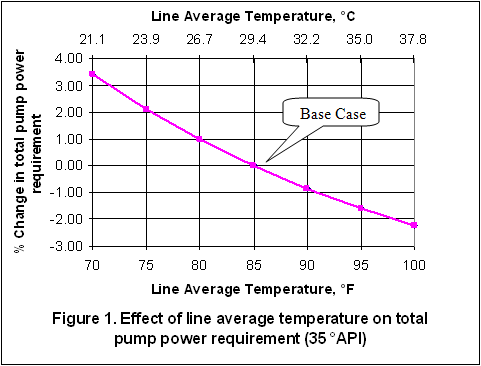

To study the effect of the line average temperature on the pumping power requirement, an in house computer program called OP&P (Oil Production and Processing) was used to perform the calculations as outlined in the March 2009 TOTM. For a 35 °API crude oil in the pipeline described in the preceding section, the required pumping power was calculated for the line average temperature ranging from 21.1 to 37.8 °C (70 to 100 °F). For each case, the required pumping power was compared with an arbitrary base case (85 °F or 29.4 °C) and the percentage change in the pumping power requirement was calculated, accordingly. Figure 1 presents the percent change in power requirement as a function of line average temperature. There is about 5% change in the pumping power requirement for the temperature range considered.

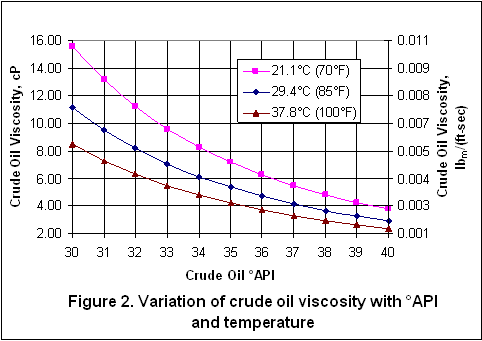

Note as the line average temperature increases, the power requirement decreases. This can be explained by referring to Figure 2 in which the oil viscosity decreases as the temperature increases. Lower viscosity results in higher Reynolds (i.e. Reynolds number ![]() is the ratio of inertia force to viscous force); therefore, the friction factor decreases (refer to the Moody friction factor diagram in the March 2009 TOTM).

is the ratio of inertia force to viscous force); therefore, the friction factor decreases (refer to the Moody friction factor diagram in the March 2009 TOTM).

Case Study 2: Effect of Variation of Crude Oil API

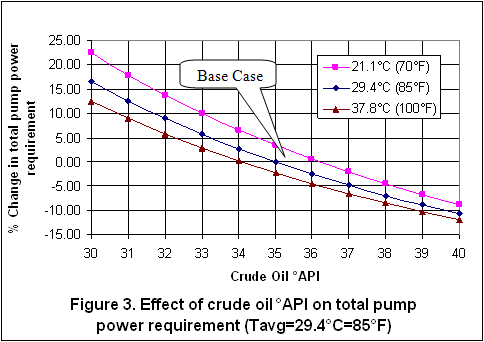

In this case, the effect of crude oil °API on the total pump power requirement for three different line average temperatures was studied. For each line average temperature, the crude oil °API was varied from 30 to 40 and the total pumping power requirement was calculated and compared to the base case (35 °API and average line temperature of 29.4°C=85°F).

For each case the percent change in total power requirement was calculated and is presented in Figure 3. As shown in this figure, when °API increases the total power requirement decreases. This also can be explained by referring to Figure 2 in which the crude oil viscosity decreases as ° API increases. The effect of viscosity is more pronounced at lower line average temperature (i.e. 21.1 °C or 70°F). Figure 3 also indicates that there is about 25 % change in total power requirement as °API varies from 30 to 40 °API. This is a big change and should be considered during design of crude oil pipelines.

Discussion and Conclusions

The analysis of Figure1-3 indicates that for the oil pipeline, the pumping power requirement varies as the crude oil °API changes. Increasing °API or line average temperature reduces the crude oil viscosity (see Figure 2). The reduction of viscosity results in higher Reynolds number, lower friction factor and in effect lower pumping power requirements.

In practical situations, an originating station takes crude out of storage and the midline stations taking suction from the upstream section of pipeline. In some parts of the world, the suction temperature to the originating pumps is +38 °C (+100 °F) but the temperature to the midline station is ground temperature (this assumes a buried line below the frost line) approximately 18 °C (65 °F). The originating station will always be more affected by temperature because storage will follow ambient – whereas the midline station will operate at notionally constant temperature +/- 5.5 °C (+/- 10 °F) in the lower 9 °C (48 °F). For the case studied in this TOTM, the number of pumping stations varied from 2.5 to 3.2.

In light of the above discussion, a sound pipeline design should consider expected variation in crude oil °API and the line average temperature.

To learn more about similar cases and how to minimize operational problems, we suggest attending our ME44 (Overview of Pumps and Compressors in Oil and Gas Facilities), ME46 (Compressor Systems – Mechanical Design and Specification), PL4 (Fundamental Pipeline Engineering), G40 (Process/Facility Fundamentals), G4 (Gas Conditioning and Processing), and PF4 (Oil Production and Processing Facilities) courses.

By: Dr. Mahmood Moshfeghian

Hello,

I used Pipesim to simulate the same case:

160.9 km (100 miles) pipeline with an outside diameter of 406.4 mm crude oil flow rate is (170,000 bbl/day). Wall thickness is 6.12 mm, wall roughness is 51 microns.

You mentioned that the pipeline design pressure is(1300 psia) with a maximum operating pressure of (1170 psia). According to Pipesim, the back pressure is between 3115 and 3767 psia for 100 and 70 F which is way abovve the MAOP you mentioned. The landing pressure I used is 1 atm.

AMATUZIO had ample opportunity to witness synthetic lubricants in action. API “SN” introduced October

1st, 2010 matches ILSAC GF-5 fairly closely.

This is why the old practice of changing straight grade oils to a

heavier viscosity in the summer and a lighter viscosity in the winter is no longer necessary.

Knowing the requirements and the choices you

will have to make will give you a head start prior to enrolling in your certificate program.

For instance, a school nurse gets a fixed salary with small yearly increases,

but gets excellent benefits from the state

or county that includes a generous vacation package and

retirement plan. After all, what good is training if your news skills do not get used.

Enhance the effect of an elliptical machine

as a 24hr fitness trainer, by deciding upon a machine that also capabilities handlebars for a incredibly

effective total human body exercise. Consult with your physician about doctor prescribed medicines and put together a support group.

Get ready to become fit and have an amazing immune system that will make sure your visits to the doctor cue to illnesses are reduced

significantly.

You ought to be a part of a contest for one of the most useful sites online.

I most certainly will recommend this blog!

Hi there colleagues, how is everything, and what you want to say about this post, in my view its actually

remarkable in support of me.

Listen up. This could certainly seem critical, but nevertheless I strongly tell you to reassess the things you just mentioned. I totally disagree with you. Email me at vengasbong@gmail.com

I carry on listening to the newscast speak about getting free online grant applications so I have been looking around for the most excellent site to get one. Could you tell me please, where could i acquire some?

Superb web site. Lots of valuable details here ISO Certification Consultants, ISO Certification Consultants Dubai uae Abu Dhabi, ISO 9001, ISO 27001, ISO 20000, ISO 14001, OHSAS 18001,ISO 17025, HACCP, ISO 22000, ISO 50001, EnMS, ISO Training Services, Management System Certification, ISO Consultant Dubai, ISO Certification Services in Dubai, ISO Consultants in Abu Dhabi, ISO Consultants in UAE, ISO 9001 Certification in Dubai, ISO Certification in Abu Dhabi, ISO Training Dubai, ISO 9001 Consultants in UAE, ISO 50001 Consultants in UAE, ISO 27001 Consultants in UAE, ISO 20000 Consultants in Dubai, ISO 22301 Certification in Dubai, ISO Certification Consultants in UAE, ISO 17025 Consultants UAE. Now i am sending the item to some associates ans moreover discussing with delectable. Not to mention, appreciate it on your hard work!

スーパーコピー 韓国 場所 mh4 http://www.wtobrand.com/otyd1.html

I’m not sure why but this weblog is loading extremely slow for me. Is anyone else having this problem or is it a problem on my end? I’ll check back later on and see if the problem still exists.

This design is spectacular! You certainly know how to keep a reader entertained. Between your wit and your videos, I was almost moved to start my own blog (well, almost…HaHa!) Fantastic job. I really enjoyed what you had to say, and more than that, how you presented it. Too cool!